Axcaliber Saw Blades - Choosing The Right One For You

You may be thinking, why do I need help choosing a saw blade, surely they all do the same job? Although correct in the sense that they all cut wood, this is also very wrong. To get the best results, you need to pick the right blade for your task. Here we take a look at our very own range of Axcaliber saw blades and give you the information you need to make the right choice.

The Axcaliber range of TCT circular saw blades offer an unmatched blend of choice, cutting performance and price. Manufactured in one of the most advanced facilities in the world, they are produced to the highest standards using the finest materials available. With the range covering everything from hand held power tools right up to large panel saws, you can be certain to find a blade to suit every requirement. The range is in three parts, Contract, Premium and CutPro.

The Contract Range

The Contract range is from 165mm to 355mm. This covers everything from hand held circular saws, (including special thin kerf blades for cordless machines) right up to medium sized workshop circular saws. These blades feature tensioned, ground plates with laser cut arbor holes and anti-vibration slots for smooth running. Fine, micro grain TCT tips are accurately brazed onto the plate with a CNC welding machine before being automatically ground to a razor sharp edge. These blades are available in a wide range of sizes, with a choice of blade types in every size. You will also find some specialist blades for mitre saws and cordless tools.

The Premium Range

The Premium range is from 254mm to 400mm and is aimed very much at the professional and industrial user. Manufactured in a similar way, each plate is ground to an exceptional standard of accuracy, having a blade run-out of no more than 0.10mm on the very largest size. The Premium blades will give an exceptional cutting performance combined with a very reasonable price for such high technology blades.

The main features of Premium Saw blades

Increased Accuracy

Laser cut steel plates which are roller tensioned then ground for increased accuracy.

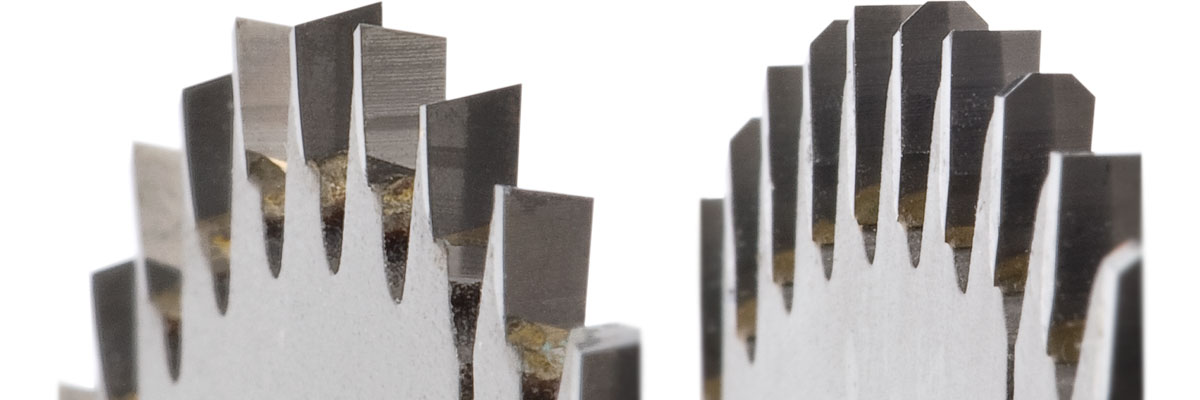

Impact Resistant Tips

TCT tips copper and silver sandwiched brazed on. This means the tips are impact resistant so there's less chance of them becoming detached.

Numerous Sharpening

Extra large Luxembourg Micro Grain tungsten carbide tips, CNC ground with diamond grinding wheels allowing up to 20 sharpens. A blade sharpening service is provided by all of our stores for a minimum of cost.

Noise Reducing

Resin filled laser cut noise reduction slots to prevent whistling. These blades are recognised by the HSE as an invaluable method of reducing workshop noise.

Tooth Configurations

Available in a number of different tooth configurations - course low tooth count for ripping work, general purpose a medium tooth count and fine high tooth count for finishing work.

Circular Saw Blade Terms

Tooth Geometry

With either alternate top bevel ground (ATB) or top centre ground (TCG) depending on the blade type, this often overlooked feature ensures best performance for each application.

Alternate Top Bevel Ground (ATB)

Our coarse tooth blades are all alternate top bevel ground, creating a sharp cutting point and edge for a better cut quality without chipping or splinters. Generally used for cutting natural timber, plywood, veneer or hardboard.

Top Centre Ground (TCG)

Top centre ground or triple chip grind as some call it are found on our finer tooth blades. They combine a balanced cutting force, low tooth drag and free chip flow to eliminate chipping in brittle materials such as chip board and laminates. Used to achieve smooth cuts in hard materials such as MDF.

The CutPro range

Designed for first class results in all natural timbers and man-made boards, CutPro blades are the perfect choice for professional use. They feature micro-grained TCT tips while the resin filled, laser-cut plates significantly reduce noise while cutting. The triple brazed Luxembourg Tungsten Carbide teeth offer greater impact. Lastly, a faint tensioning ring halfway across the plate indicates where each individual blade undergoes pre-stressing to guarantee smooth running. With the same fantastic features as the Premium range, CutPro blades also deliver a higher sheer angle. The 35°top level angle ensures an outstanding finish and performance and delivers a cleaner cut and less breakout on the underside.

When it comes to CutPro blades there's a choice of types. Firstly there's 160mm blades designed for track saws. These are ideal for Festool saws. Next, there's 165mm blades. These blades are available in standard kerf or thin kerf options. The latter is suitable for battery operated track saws and circular saws. All other size blades are designed for chop saws. These are only available in negative rake versions.

Which saw blade do I need?

There are several types of blade with each having a choice of use as well. There is a brief explanation below:

Rip Blade

These blades have the least number of teeth for the diameter, i.e. 250mm, 24 teeth (24T). They are used for cutting with the grain in natural timbers, such as cutting down the length of a board or a baulk of timber. The tooth spacing is required to allow the waste material to be cleared from the cut, preventing the blade from binding and overheating. These are not suitable for cutting across the grain or for cutting ply or chipboard.

General Purpose or Combination Blade

These have more teeth for the diameter, again using a 250mm blade as an example it would have around 40 teeth (40T). These blades can be used for all types of cutting in natural timbers, however you will not get the best results possible. Ideal though for tasks not requiring a fine finish and well worth considering if you frequently need to cut with or across the grain.

Crosscut or Fine Blade

Again, more teeth for the diameter, say 250mm X 60T. Used for cutting natural timber across the grain, creating a smooth, tear free cut. Can also be used for ply and all other man made boards. Not suitable for cutting with the grain as the long shavings created will clog the blade, with the result being a blade overheating and possibly suffering damage.

Fine Crosscut Blade

Sometimes known as an Extra Fine blade, these have the most teeth (i.e. 250mm x 80T) and will give the cleanest possible cut across the grain in natural timbers. These are especially good for sizing panels. Often used on panel saws in conjunction with a scoring blade on faced or veneered boards. The tooth design is specially designed to create a perfect edge to the cut, with no chipping or tear out.

Thin Kerf Blade

These are much thinner in section and are best suited to mitre or chop saws that have no riving knife. The thin blade section means that much less material is removed during the cut and so less power is required. Commonly used on battery powered hand held circular saws to lengthen the battery life between charges. For the busy contractor on site they make a lot of sense. They also work well on lower cost benchtop circular saws, just be aware that if a riving knife is used it must be thinner than the kerf of the blade.

Negative Rake Blade

Perfect for use on mitre saws and radial arm saws, the negative rake angle of the tooth prevents the blade from “climbing” over the work. The cut entry is much softer which makes the machine safer to use. These blades can also be used for aluminium tube and extrusions. The negative tooth angle prevents the collapse of the tube or extrusion wall. These are suitable for cross cutting work only.

PCD Diamond Saw Blade

Suitable for handheld circular saws, mitre saws and saw benches, the cutting teeth of Polycrystalline diamond (PCD) are far harder with up to 20x the life of a comparable TCT blade when used for certain applications. PCD makes excellent economic sense for professional trade use. Each PCD blade features resin filled expansion slots to reduce noise. Furthermore, the extra large gullet design improves the waste removal rate, for increased feed speed.

Ideal for the construction trade, PCD diamond blades will effortlessly cut through fibre cement. What's more, if you need to cut through gypsum or cement impregnated boards, it is no problem with these blades. They are perfect for cutting fibre cement boards/ cladding such as 'Hardiebacker', 'HardyPlank board','Marley Eternit', 'Cedral Lap Board', 'Cembrit', 'Minerit' etc, as well as compressed concrete panels.

A selection of Axcaliber Circular Saw Blades

-

Axcaliber CutPro TCT Saw Blade Thin Kerf - 160mm x 1.5mm x 20mm 52TFrom £30.48 £25.40

-

Axcaliber Contract TCT Saw Blade - 165mm x 1.5mm x 20mm 12TFrom £7.98 £6.65 From £6.38

-

Axcaliber Contract TCT Saw Blade - 165mm x 1.5mm x 20mm 24TFrom £10.18 £8.48 From £8.14

-

Axcaliber Contract TCT Saw Blade - 250mm x 2.8mm x 30mm 40TFrom £26.38 £21.98 From £21.10

-

Axcaliber Contract TCT Saw Blade - 250mm x 2.8mm x 30mm 60TFrom £31.48 £26.23 From £25.18

-

Axcaliber Contract TCT Saw Blade Thin Kerf - 254mm x 2.1mm x 30mm 48TFrom £25.38 £21.15 From £20.30

Circular Saw Blade Round Up

The old saying that your saw is only as good as the blade you put in it is true in many cases and with the Axcaliber range of saw blades you will not be disappointed. With a huge variety of high quality blades on offer, you will be certain to find a blade for your task that will perform time and time again.

The recommended speed for the 200mm rip blade is 9000rpm. My saw will not achieve that. Will quality of cut suffer at 7125 rpm?

Hi Sam, the figures on saw blades are usually the recommended maximum speed and anywhere between 7,000 - 9,000rpm for wood cutting is ok. The quality of the cut will be slightly worse than at the highest speed but the difference will be negligible and it's more than likely you won't notice it at all.

I hope this helps with your question. If you have any more feel free to ask.

Thanks, Mark

I'm a vulture and scavenge timber - sometimes there are nails, to be honest there are always nails. A few years ago a friend was telling me of naily wood blades. I know the excalibur range but they do not recommend use in other than their own machines (torque????).

Are they still made and if so do you do them (305mm)..

Hi foxuk, the Axcaliber blades that we sell are made solely for woods and man made chipboard, so run at very high speeds (7,000 - 9,000rpm). The TCT tips also sit proud, slightly above the edge of the blade and so don't have the support that you will find on specially made nail blades. This means that they will likely shatter if they encounter a nail or other foreign object.

Unfortunately we don't stock blades that are available for this purpose. You will also find that many other suppliers stock these blades for hand held circular saws and mitre saws only. I have, however managed to find a supplier that has nail resistant blades from 150mm - 610mm at this site..... http://www.flinn-garlick-saws.co.uk/acatalog/on_Walker_Industrial_Circular_Saw_Blade_Nail_Resistant.html

I hope this helps with your enquiry.

Thanks, Mark

Thank you Mark.

The price does tend to add another variable to upcycling... I may have to invest in one of those metal detector thingies instead.

You definitely take customer service to a higher level than most.

Thanks for your kind words. We always try to keep our customer service to the highest levels.

Sorry I couldn't help you further. All the best with your scavenging.

Mark

I have Axminster Trade MJ12-1600 MKII saw. Now it using a 90mm scoring blade set. I have purchsed a said saw second hand and it has never had blades changed from new. As a result the previous owner clearly hadn't followed the instructions and set up scouting blade without shims. I can only assume, that these have been binned as owner (not following the manual) did not know what these were.

I am trying to source the second set of scoring blades, so that I could not only be able to resharpen the original set but also have a set of spacer shims. However here lies the problem. I can only find (including axcaliber range) 80,100, or 120mm sets. it seem that 90mm sets are rather odd size.

Can you please inform me, if I can still buy a set go 90mm blades from Axminster?

Many thanks.