Glues And Gluing: Part One

As part of series of blogs on The Knowledge, Rob Stoakley takes you through the numerous glues on offer at Axminster Tools and which is the right adhesive for your projects.

Step back in time

The art of wood mangling has been around almost since the very dawn of civilization. Certainly the Egyptians knew how to build stuff. The Egyptian Museum in Cairo has some unbelievable pieces made about 3,500 years ago. It’s also very likely that other early civilizations, such as the Chinese, produced furniture and various artefacts. However, as far as I’m aware, very little has survived for us to examine.

The ancient Egyptian and Chinese craftsmen knew how to make glue from animal parts such as fish, hooves, horn and skin. This is known as ‘animal glue’ which still exists today as Pearl glue. After the fall of Rome in the 5th century, the use of animal glue fell into decline until the Renaissance, when wooden furniture began to be made in quantity.

Animal or hide glue has been in use for thousands of years and was still the only glue available until quite recently. Until the modern chemistry profession dipped a toe into the sticky waters. The 20th century saw the rise of a vast range of different industrial adhesives, many of which we’re familiar with and to which we probably don’t even give a second thought. But which ones are relevant to the modern woodwork ‘shop?

The reversible fix

Strange as it may seem, pearl glue is still the preferred choice for the antique restorer, because it’s reversible. By applying heat or steam, the joint will come apart, no matter if the piece is centuries old. Conversely, most modern glues are not reversible and pieces built using them will cause future conservators some ticklish problems in a couple of hundred years.

Glues which are to a certain extent ‘reversible’ are those which are intended for interior use only, such as Titebond Original or ‘yellow’ glue. This is excellent stuff and makes a bond which is stronger than the wood itself. But bring it anywhere near water and it will start to disintegrate, as I found out when I used it to do some veneering. When I later cleaned off the veneer tape with a nylon scourer and hot water, I noticed the wood starting to bubble! For a comprehensive overview of Titebond adhesives, see our Buyer’s Guide.

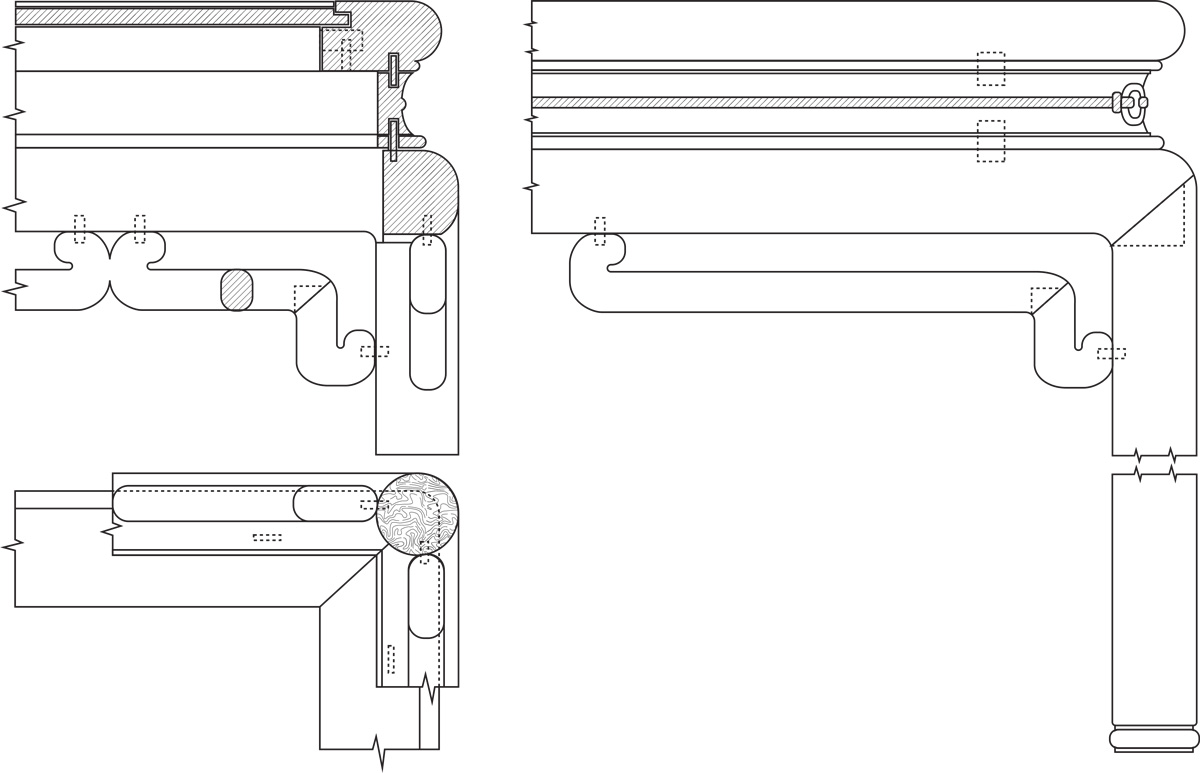

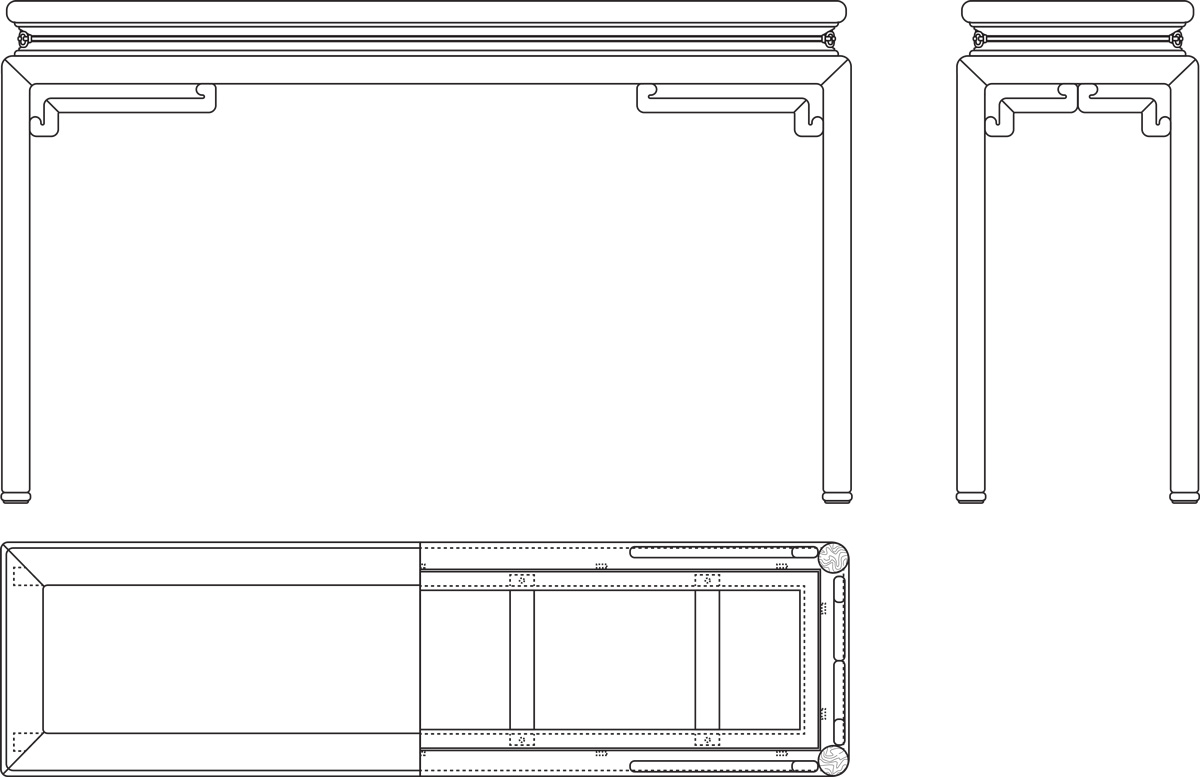

Reversible glues also have a downside, as the Chinese discovered. Surviving pieces of early furniture are built without any glue whatsoever, instead relying on devious and extremely complex mechanical joints. Had they been made with hide or fish glue, they would have fallen apart centuries ago in the heat and humidity of the Far East. ‘Chinese Domestic Furniture’ by Gustav Ecke gives a fascinating insight into how these masterpieces were made.

Issue of open time

One of the main issues with glues of any sort is ‘open time’. This refers to the length of time that the glue is usable before it starts to go off or set. This can vary from a few minutes to hours, depending on glue and the temperature of the workshop. The warmer the workshop, the shorter the ‘open time’ which is the reason why complicated glue-ups are so fraught!

PolyVinyl Acetate

By far the commonest form of adhesive developed during the last century is PVA, or PolyVinyl Acetate. This is more commonly referred to as ‘white glue’. It’s usually the first choice of glue in many workshops. It is universally available from a huge number of manufacturers and in many different guises. But essentially they all have similar properties. These include easy application, a very strong bond, easy to clean up, and a relatively short open time. Some are water resistant or waterproof.

Urea & Phenol Formaldehyde

Better known under its trade name of Cascamite, urea formaldehyde glue usually comes in the form of a white powder, which must be mixed with water to a precise consistency. Storage time in the container is relatively short, but when mixed correctly, the open time can be several hours. Although it gives a very strong, water resistant joint, the disadvantage of this stuff is that it sets like glass. This makes it quite difficult to clean off the excess when it has set hard. In addition, anything left over in the mixing pot will be wasted. The other form of this glue is Aerolite 306 where there’s a separate powdered resin (which must be mixed with water) and liquid hardener; storage times are subsequently much longer. Where continuous immersion under water is required, i.e. a boat hull, one very good option is to use a phenol formaldehyde glue.

Thus far, I’ve only briefly examined a few of the common types of glue found in a workshop. I’ll be looking at more adhesives in the next instalment.