Morticers

A mortice and tenon joint is a fundamental method of joining wood together; it is simply a rectangular tongue (the tenon) which slots into a corresponding hole. The technique is so old that these joints can clearly be seen in the Museum of Egyptian Antiquities on a hunting stool that once belonged to the boy king Tutankhamun who died over 3000 years ago.

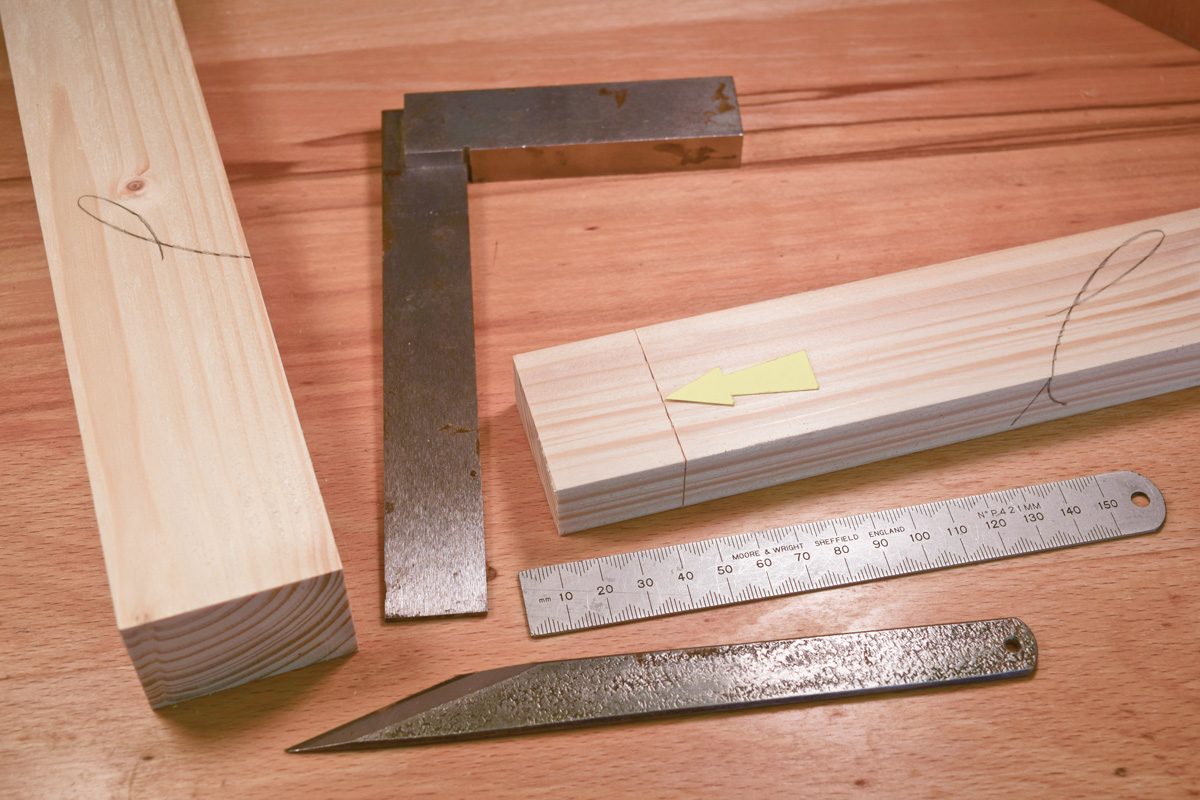

For centuries, the joint had to be cut by hand and some still do prefer to chop out a mortice and cut a tenon using only hand tools (click here to read our guide) but it’s a slow, laborious process which can become quite tedious when there’s a lot to do.

The rectangular hole or mortice is generally considered the most awkward part to chop by hand as the hole needs to be deep and usually quite narrow. The size, type and quantity of the mortices is governed by the project being constructed. During the process of cutting, the mortice will be filled with waste chippings which have to be removed and once complete, the bottom of the hole is generally quite uneven, so care needs to be taken to see that the overall depth is greater than the tenon.

The advent of the morticing machine has speeded up the process to ensure that a very accurate cut is guaranteed every time. Whereas chopping one out by hand takes some considerable time, it’s the work of seconds with a morticer to cut out a similar sized, precise rectangular hole.

The machine and its operation

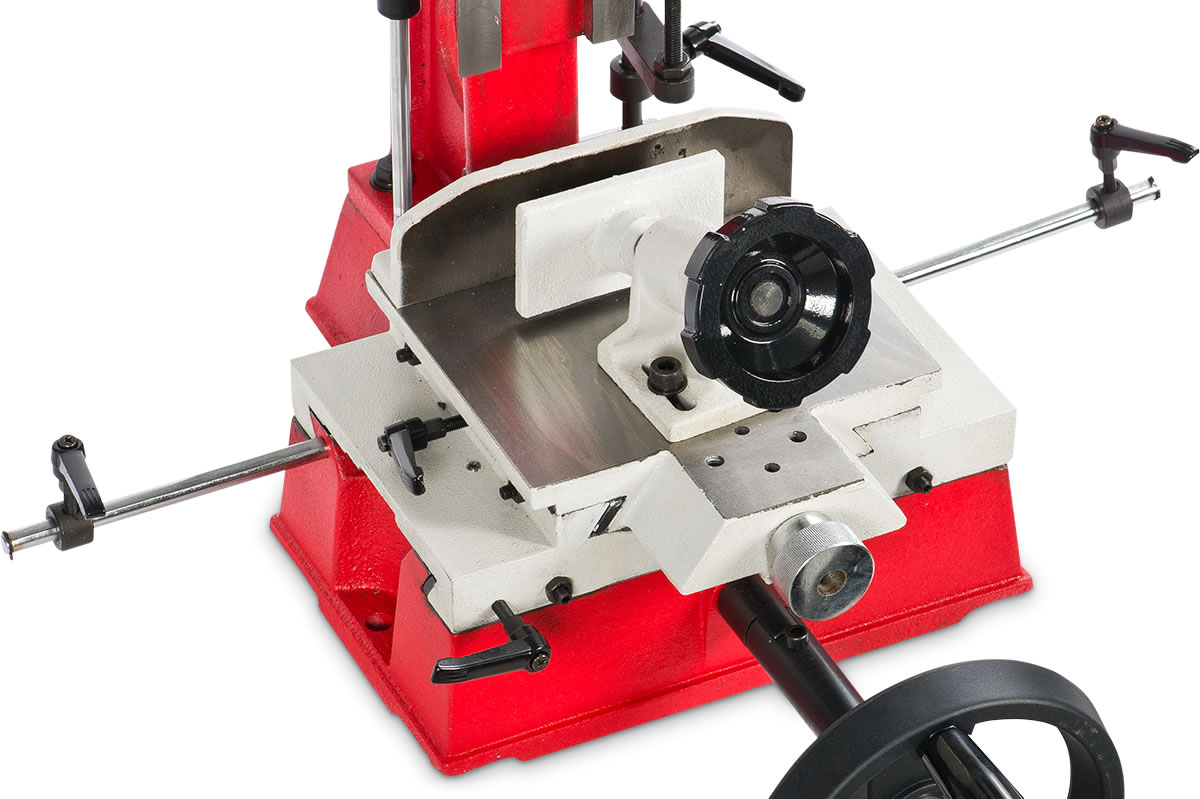

In essence, a morticer is a very simple machine, consisting of a powerful motor which is moved vertically using a lever operated, rack and pinion mechanism, with adjustable stops to set the depth of cut. Directly underneath the motor’s chuck is a substantial table onto which the workpiece is securely clamped. Depending on the model, a single or double handwheel arrangement controls both longitudinal and lateral table movement, ensuring that the chisel is in precise alignment to cut the joint.

Special morticing bits must be used in these machines and they consist of an auger bit which rotates inside a square, hollow chisel. One side of the chisel is open to allow the flute on the auger bit to expel the chippings as they’re produced.

It’s particularly important to heed the setting up instructions to allow clearance between the bit and the auger so that they always operate correctly. Watch our instructional video below:

Once the workpiece has been positioned, the first square hole is cut to the correct depth, with the auger simultaneously ejecting the waste chippings. The hollow chisel is then removed and the table moved sideways by the width of the chisel, which is then used to cut a second adjacent hole, thus enlarging the mortice to twice its width. The process is repeated several times along the length of the workpiece enlarging the hole each time by the width of the hollow chisel until the final cut has been machined and the mortice completed.

In common with many other machines, morticers are built using a substantial amount of cast iron which not only dampens vibration but adds significantly to the overall weight. Even the smallest Axminster Hobby Series machine is an impressive 42kg; the larger capacity floor mounted Axminster Trade and Industrial rated morticers are considerably heavier. It’s therefore essential to pay attention to the correct lifting procedures and seek assistance when moving or installing them.

The tenon

Being rather more exposed, the tenon is easier to produce and can be accurately made using a router table, spindle moulder or a dedicated industrial rated 3-head tenoner as found in many professional joinery ‘shops where there’s a requirement for this type of machine.

Chain morticer

On some projects, for example on green oak timber framing work, the workpiece is generally too large to lift, so the morticer needs to be brought onto site and used in situ. This is where a chain morticer is used and is invaluable for this type of application. It consists of a vertically mounted chain saw which is plunged into the wood and then traversed to make the mortice.

Conclusion

Chopping mortices by hand is time consuming, especially if the project is a large one and there are a lot of them. Even worse is when you’re up against time constraints. So whether you’re an amateur weekend woodworker or a full time professional in a production workshop, the workload can be eased as there’s sure to be an Axminster morticer to suit every requirement and pocket.

Hi their guys what about showing us how to set up the hobby morticer so it runs great I always seem to cut the mortice out of line the instructions I got were crap why not make a video showing us how to tweak it Ive been working with wood and metal for decades and I think cheep crap can be made to work better by tweaking especially since so much stuff from china is flooding the world market. so we do need tweak videos. I make my axminster 250 hobby saw run like a purring cat also fixed the evil dust problems yes maybe Iv lost the warranty but it now runs great. Also does any one know fow to sharpen plug cutters and forstner bits as china has struck again cheap muck is everywhere even in the good old dealers we used for years have had to resort to Chinese junk whos not thought wow a boxed set of plug cutters and bought them only to throw them straight in the bin after the woods set on fire well just some thought lets see the tweeks on tools you've bought .