Pocket holing with the new UJK Technology Pocket Hole Jig

There’s always a project being made in the ‘shop, and with the current one, light, as they say, can be seen at the end of the tunnel. The job is a tall chest of drawers in American cherry. The carcase is being made in MDF, veneered with 2mm thick band-sawn veneers. This sits on a small plinth, which needs to be fixed to the carcase.

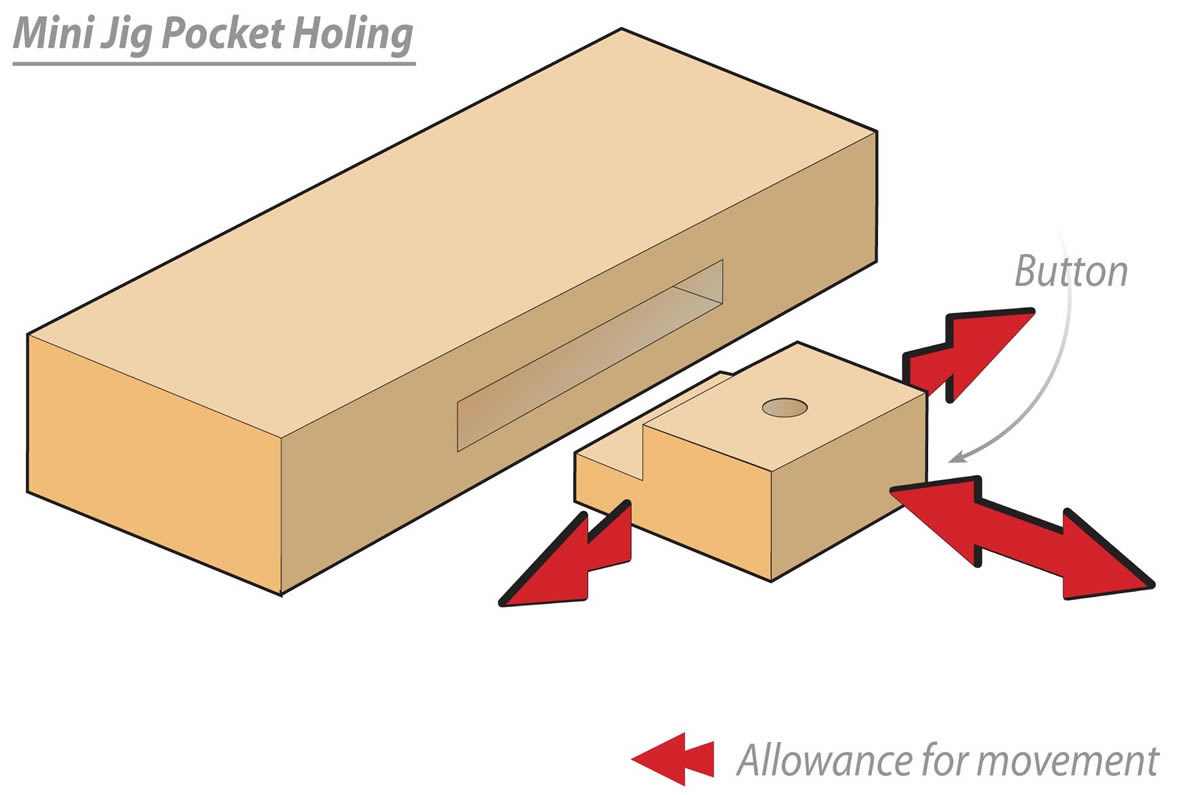

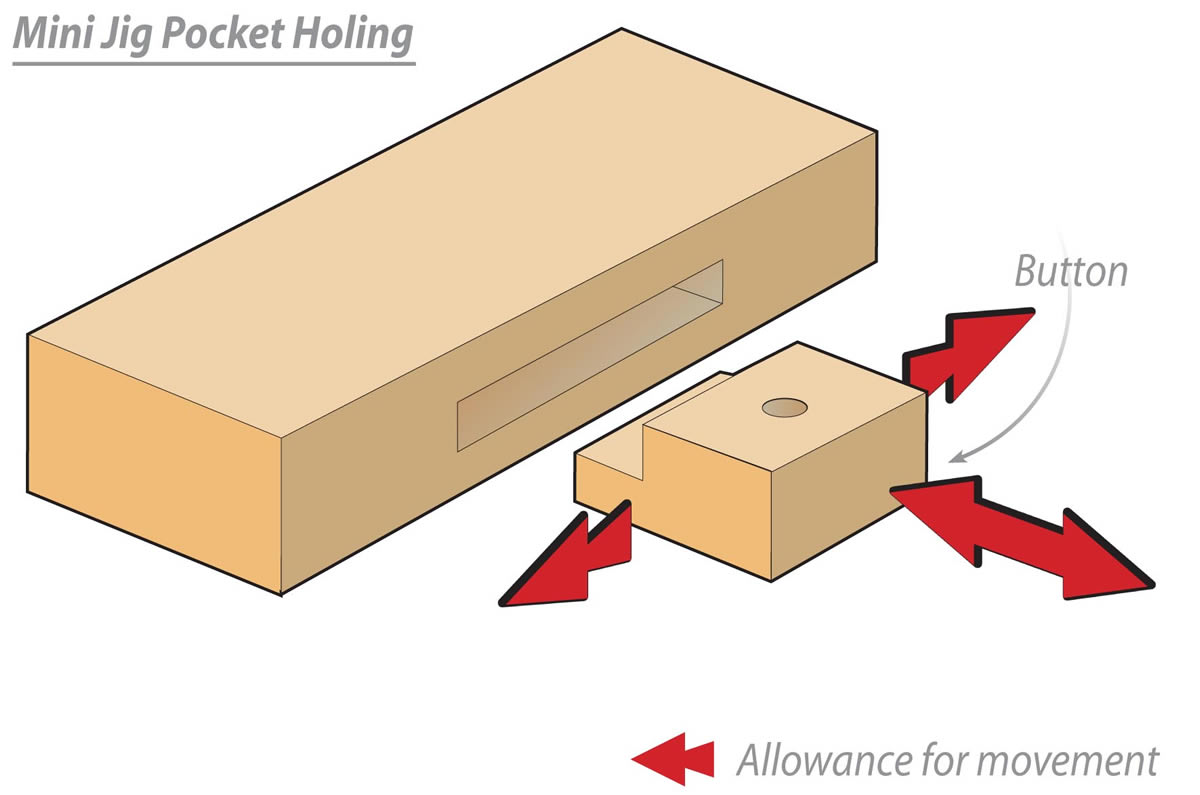

The traditional way is to use a number of ‘buttons’, as shown in the drawing. The advantage of this is they will allow for significant movement if solid timber has been used in the construction.

The mortice in the rail is machined longer and deeper than the tenon on the button. This means that it will slide quite easily in both horizontal planes, even when it’s screwed to the carcase.

Opting for pocket holes

However, in this case, there isn’t any solid timber. Therefore,I decided to try a slightly different approach and use pocket holes. These are awkward little blighters to make freehand. However, the recent introduction of the UJK Technology Mini Pocket Hole Jig has made this task easier.

I used an adjustable square to measure a 6mm offset from the top of the rail. I then used the special UJK Technology drill, complete with its depth collar, to make the holes. It’s important that the drill is always used on the highest speed setting and the drilling needs to be done carefully, frequently clearing the debris. If not, the small pilot drill is liable to break off!

A couple of pocket holes on each side are going to be more than enough to secure the plinth to the carcase. It’s also advisable to use a UJK 150mm T20 Torx screwdriver bit to give clearance and some suitable washer headed pocket screws, of which there’s a very good selection.

I’m not normally a big pocket holer, but this little jig seemed the right tool to use for this application, so I’ll probably use it again on another future project.