Axminster Tools were the proud recipients of the award for Top Employer in the retail category at the School Leaver Awards 2020. We beat off some big competition in the form of DFS, Harrods and Specsavers. Axminster Tools were also ranked 54th in the Top 150 Employers above huge organisations like John Lewis, Coca Cola and British Airways. A great achievement for a family run company based in a rural corner of East Devon.

The School Leaver Awards

The School Leaver Awards celebrate the top employers and training providers for school leavers on apprenticeship programmes. Judges use the opinions of apprentices and school leaver trainees from 150 UK organisations to pick the winners. Most importantly, the aim of the awards is to raise the standard and understanding of what apprenticeships can do for individuals and also for employers. Axminster Tools vowed to help spread the message by sharing our successes. We are extremely proud of our apprenticeship programme; it's a great way to nurture talent. We hope that by winning this award, other potential apprentice employers will see just how much we value our school leavers and future talent.

Apprenticeships at Axminster Tools

We challenge our apprentices every day, working with highly skilled people who pass on their knowledge and expertise. It's a real job with real responsibilities and we're delighted with what our apprentices achieve. As a result, many of our former apprentices are at the top of their game, in highly skilled positions.

Lydia Burrough, Accounts Apprentice since September 2015 completed her AAT Level 4 in 2019. Upon completing her qualification, Lydia was nominated in recognition of outstanding performance in accountancy at the Apprenticeship & Employer Awards 2020. When asked about her experience she said:

“I didn’t want to go to university, so the apprenticeship gave me the opportunity to learn as I earned, and improve my work skills. I really enjoyed it and I can see my career path developing, especially with the mentoring and support I am given here.”

Since our apprenticeship scheme began in 2006, Axminster Tools have recruited 27 apprentices; 24 of whom have completed their apprenticeship and continued within the company. Jane Boulton, HR Director at Axminster Tools said

"To be recognised as the top apprentice employer in retail is a real honour. As a company we have seen huge benefits from our apprenticeship scheme; we love to nurture potential. To help people take their raw talent much further, to grow, develop and learn all the things they need to become an invaluable part of a team".

For more information on apprenticeships with Axminster Tools go to axminstertools.com/careers.

Axminster Tools were the proud recipients of the award for Top Employer in the retail category at the School Leaver Awards 2020. We beat off some big competition in the form of DFS, Harrods and Specsavers. Axminster Tools were also ranked 54th in the Top 150 Employers above huge organisations like John Lewis, Coca Cola and British Airways. A great…

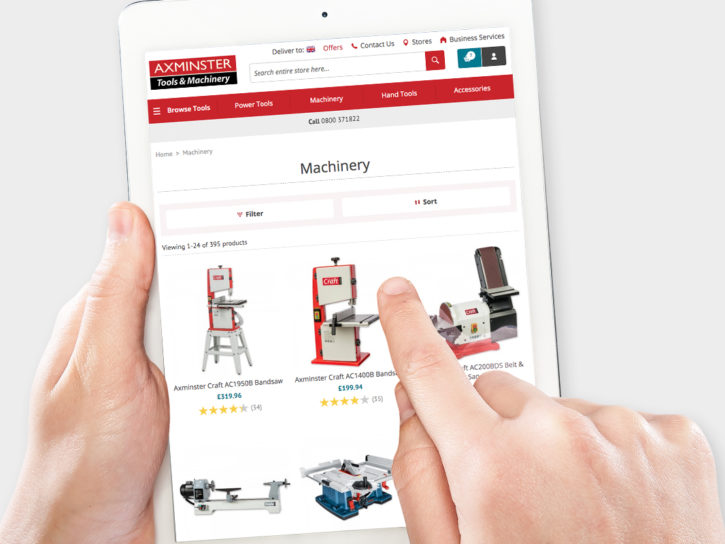

Have you seen our new look?

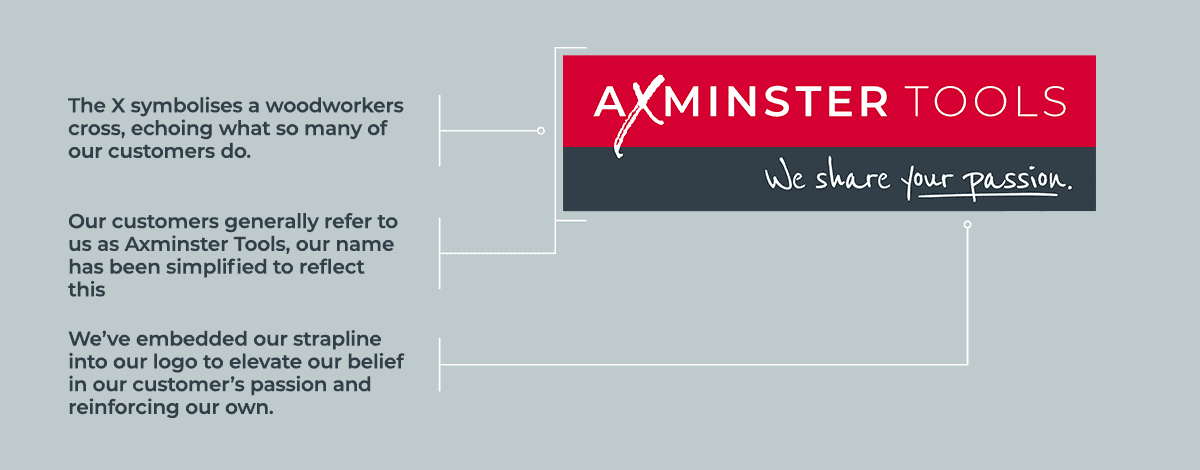

This is the latest in a line of updates at Axminster Tools to help better represent our offering of woodworking products to you, our customer. Our new logo, updated website and change of domain illustrates our vision to make purchasing tools as simple as possible and better encompasses our brand overall.

The first update took place in the spring when we changed our domain from axminster.co.uk to axminstertools.com. The new domain is more descriptive in terms of who we are and how our customers like to refer to us and the .com better serves our growing international customer base. In the summer we launched a brand new website; as well as a sleek new appearance, users will notice improved navigation and search abilities. Now, as we move into autumn and in line with our new 2020/21 catalogue we've shared our updated logo. Our brand has built a strong reputation over the years so our new identity is an evolution of our previous logo, which was well recognised.

Our logo through the years

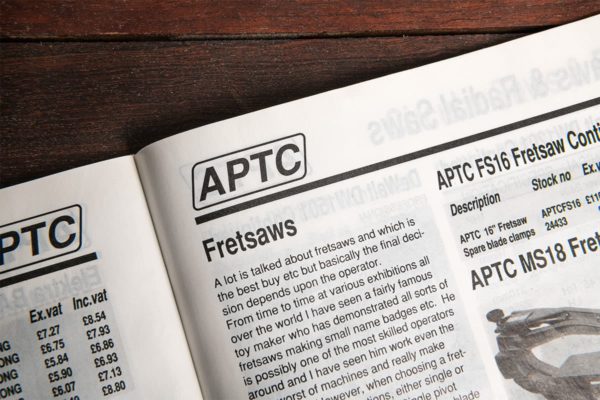

We couldn't miss the opportunity to take a look at our logo through the years and reminisce about how far we've come. Axminster Tools actually started life in business carrying out light engineering production and electrical assembly work with a small tool shop as a sideline. Before long the production work took a back seat as the demand for tools grew. In the early 1970s Axminster Power Tool Centre was born out of a small shop in the market town of Axminster, Devon. At the same time, the family run business made its first venture into mail order with a single page leaflet offering cutting discs and grinders. It wasn't until 1992 that we produced the first edition of what is now our well known catalogue. It was through the production of the catalogue that the logo started to evolve with the business. The first was just a simple acronym of the name Axminster Power Tool Centre.

1995

By 1995 the logo had changed to incorporate the full business name and better describe our offering at the time.

1998

In 1998 we produced our very first full colour catalogue. The logo took on the familiar red colouring, which would remain a feature on future logos.

2000

At the turn of the century, we made a slight tweak to the logo, giving it a fresh new look. The black and red logo was born.

2011

The logo stayed this way for a number of years until 2011 when our focus steered towards developing our own brand tools and machinery. We had been innovating and manufacturing tools and machinery for a number of years but our onsite product development and manufacturing really started to grow at the beginning of the last decade. We dropped the 'Power' and became Axminster Tool Centre.

2014

In 2014 to reflect our ever growing offering for machinery and build our reputation in that market, we became Axminster Tools & Machinery.

2020

Our logo and brand has continued to evolve to encompass the business and our customer. Let's take a closer look.

Our logo may have changed over the years but our focus has always been the same; we share your passion for great craftsmanship and a job well done. We strive to offer the products you need, the knowledge you trust and the committed service you deserve.

Have you seen our new look? This is the latest in a line of updates at Axminster Tools to help better represent our offering of woodworking products to you, our customer. Our new logo, updated website and change of domain illustrates our vision to make purchasing tools as simple as possible and better encompasses our brand overall. The first update…

A carver from Plymstock in Devon has been showing his appreciation to the NHS by hand carving and donating wooden plaques to hospitals. Johnathon Whittaker was inspired to design and carve his first 'NHS hero plaque' while out clapping for key workers, one Thursday evening. His son Alex suggested he should carve something, and so he did. He shared his idea on social media and the original post received 350,000 hits in one week.

Carved By Hand

Johnathon began his career as a Civil Engineer focusing on coastal defence before he gave it up to become a full-time parent. He started his own business around 12 years ago, specialising in outdoor furniture and garden structures.

Now a self-taught, self-employed carver, Johnathon began by carving ‘thank you’ plaques and signs in his spare time. He soon realised he had a passion for carving and his business changed direction. He moved away from his original business, Urban Garden Structures, and relaunched as Carved By Hand.

Initially, he continued with the plaques and signs but his natural talent meant he mastered new skills quickly and soon moved on to carving more intricate and detailed designs. He watched YouTube videos by established woodcarvers such as Ian Norbury and Andrew Thomas to further his skills. His portfolio consists of a multitude of wall art, pendants, seahorses, hares, whale tails, sharks, and lots of abstract pieces made from wood he finds on walks. More recently he's been working on realistic knots, horse heads, and the human form. Most of the pieces Johnathon carves are sold or on display in local shops and galleries.

An evolving skill

Johnathon has been carving for five years now and his skill set is constantly evolving. The fact that he is not a traditionally taught woodcarver leaves him free to explore with all manner of tools. He uses chainsaws, angle grinders, routers, power carving tools, knives, chisels, and rotary tools. He really likes to experiment, particularly with the finish and the use of colour and resin. His favourite wood stains are by Chestnut Products, both the traditional colours and the rainbow spirit shades.

The idea behind the design

Johnathon shares his skills and ideas through the classes he teaches in his workshop. His longest-standing student is 76-year-old Pat Waters; she has not only learned carving skills through Johnathon's classes but has benefited from the confidence that comes from learning a new skill.

Johnathon had Pat in mind when he designed his first NHS hero plaque. The idea behind the design came from an NHS advertising campaign featuring the 'S' as the familiar superhero symbol. Unbeknown to Johnathon the amount of attention the plaque would receive, he took the design and adapted it. He carved his first plaque for Pat, to let her know he was thinking of her and acknowledge everything the NHS does for her. He also thought Pat may like to have a go at carving one for herself. She has underlying health issues and has been in isolation for many weeks.

An unexpected response

The plaque received such a positive response from Pat, that Johnathon decided to make a larger version; this time for some friends who work in his local Derriford Hospital in Plymouth. It was this larger plaque that Johnathon posted on his Facebook business page, Carved By Hand. It didn't take long for requests for more plaques to start dropping into his inbox. Johnathon's partner Christie Lee Waters has been helping with the admin

We never expected to get the sort of reaction we did. It has been truly phenomenal and (I may be biased but) so well deserved. He is carving all day every day, well into the evening - although that isn't necessarily unusual. He is doing this for everyone else, not for his own benefit at all. Recognition for producing something beautiful is all he really wants.

Christie

The Woodworking Community

Johnathon has committed to carving 73 plaques himself. He put a call out on woodworking forums for carvers to join him, so that he might commit to more. If he can get enough support from the woodworking community, he would like to adapt the design and extend the gesture to care homes too.

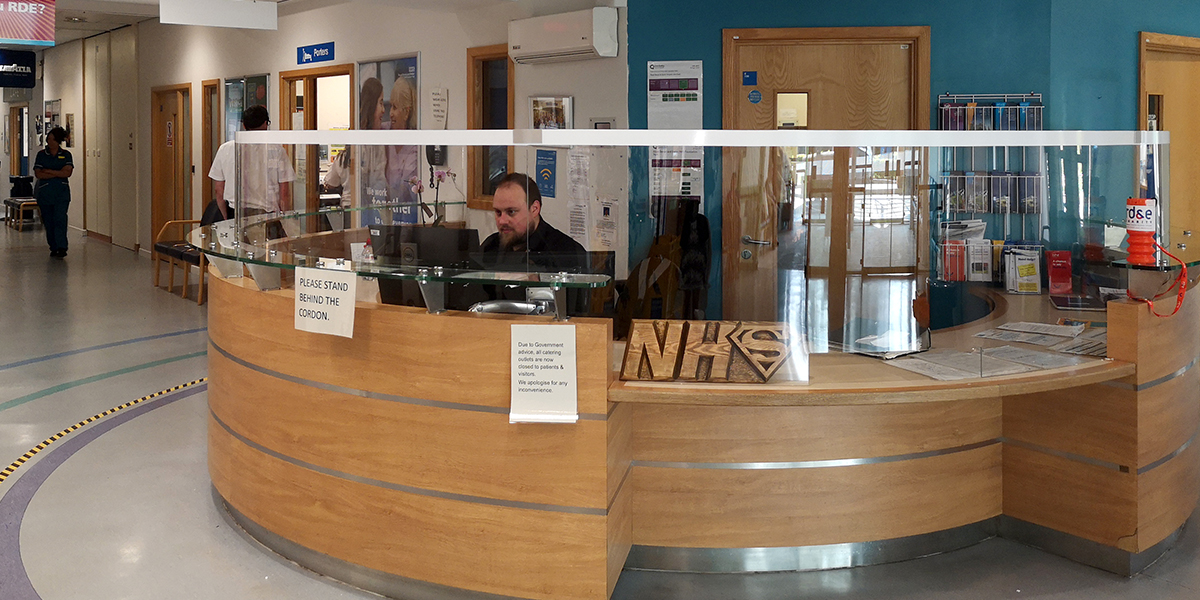

The Royal Devon and Exeter (RD&E) Foundation Trust was one of the first hospitals to receive their NHS hero plaque.

We'd like to thank Johnathon and Christie for the beautiful wood carving they donated to the hospital. Following quarantine, it's now sitting proudly in our main reception.

Spokesperson for the RD&E Foundation Trust

Axminster Tools & Machinery heard Johnathon's story and wanted to help. Supported by suppliers including Flexcut, Hermes, Mirka, DMT, Dura Grit, Kirschen, Leigh, Trend and Tormek, Axminster Tools supplied Johnathon with a bundle of tools and consumables to make carving quicker and easier

Thank you Axminster Tools, I’m blown away, the tools are a carver's dream. We can’t thank you enough and with your generosity, we’ll be able to keep on carving and donating these plaques to the amazing NHS facilities around the UK. If my designs make staff feel more appreciated at the end of a long shift, it's the least I can do.

Johnathon

How to make an NHS hero plaque

If you have been inspired by Johnathon's design and would like to have a go at making one of his NHS hero plaques, Johnathon has put together this helpful video

Coming soon - a tutorial on how to create the plaque using a router and power tools. Subscribe to Johnathon’s YouTube channel for the next instalment.

What you'll need

Tools & equipment

60 Degree V-Groove Gouge

6mm Shallow Cut Back Bent Gouge

Flexcut MC150 6 Piece Mallet Tool Starter Set - includes a 60 degree v groove gouge as mentioned above

Chisel Set - 5 to 25mm width

Abrasive - 120 and 240 grit

Large Wooden Mallet

Finishes

Liberon Woodstain

Shellac Flakes - please note, this is a large amount and will need mixing

Acrylic Lacquer

Materials

Johnathon tries to use locally sourced wood: regular pine, 2x4s and scaffolding boards. Materials that you should be able to source easily at your local store, rather than exotic wood.

Can you help?

If you think you can help Johnathon with his mission to put a smile on the faces of our key workers, please get in touch with Carved By Hand

A carver from Plymstock in Devon has been showing his appreciation to the NHS by hand carving and donating wooden plaques to hospitals. Johnathon Whittaker was inspired to design and carve his first ‘NHS hero plaque’ while out clapping for key workers, one Thursday evening. His son Alex suggested he should carve something, and so he did. He shared his…

We've changed our domain name

As a company, we’ve always believed that transparency is important. Our new domain name is more descriptive in terms of our offering of woodworking products to you, our customer. It also represents our vision to make purchasing tools as simple and frustration-free as possible and better encompasses our brand overall.

What does this mean for you?

This update strictly relates to our new domain name. To put your mind at ease, we’re the same family owned company, offering the same exceptional service you’re used to.

Firstly, you’ll see that our website and online content remains unchanged at our new domain name. For your reference, all existing links on our old axminster.co.uk domain now automatically redirect you to our new axminstertools.com domain.

With this in mind, you may wish to update your bookmarks or links to our new domain. Please note that any old links will continue to work regardless due to the automatic redirect in place and will continue to do so.

If you were not signed in to your account prior to this change you may have lost some items previously added to your basket prior to checkout. If this is the case, we apologise for any inconvenience this may have caused.

Finally, in terms of security, we want to reassure you that we will never ask for your card details or passwords whether via email or any other medium. The same applies if you have specifically requested a reset password email; we will never ask for your card details or passwords.

If you’re concerned that someone may be trying to obtain this data from you regarding your Axminster account, please contact Customer Services at cs@axminstertools.com.

Moving forwards...

Right now, we’ve only changed our domain name, but we have so many great, up and coming plans for the future. Watch this space!

If you haven’t already, why not join our Axminster Email Club and keep up to date with the latest news, products and promotions? Be the first to learn about new products, store demonstrations, events and company news, and receive great offers and personalised emails based on your interests direct to your inbox!

We’ve changed our domain name from www.axminster.co.uk to www.axminstertools.com. See how it’ll affect you by reading our short blog. As a company, we’ve always believed that information is power, and transparency is important. Our new domain name is more descriptive in terms of our offering of woodworking products to you, our customer. It also represents our vision to make purchasing tools as simple and frustration-free as possible and better encompasses our brand overall.

Builders of a one-tenth scale model of the Mayflower are on schedule to complete the project in time for the start of commemorative events to be held in Dartmouth this summer.

With work on the superstructures above deck progressing steadily, the last major element will be making and fitting the rigging.

Support for the project aims to raise awareness of the Axminster brand among regional and national boat building and model making communities. And also highlight the application of centuries-old woodworking and carpentry skills.

Lead builder, Ian Kirkwood, is excited about the prospect of seeing the completed model revealed to the public in June.

It's been a painstakingly detailed project which to date represents over 5,000 hours of volunteer work. I'm delighted to say that over the past two months we have had the support of an additional four volunteers, effectively tripling our team and we will have their support right through to completion.

Invaluable support

Ian said that the support of Axminster Tools & Machinery, and their supply partners, since the start of the project in April 2018, had been invaluable.

"The Axminster Trade specification table saw, bandsaw and extraction system helped us make steady progress right from the outset. A generous donation of tools from Lie-Nielsen, has put challenging handbuilt components within our reach. And Tormek systems have helped keep chisels and planes sharp and accurate."

Particularly helpful constructing the detailed components, are several Proxxon machines provided to the project.

The Proxxon products have been outstanding and model makers everywhere should keep them in mind. We've used the planer thicknesser, the table saw, scroll saw and mini chop saw to great effect to speed up many repetitive stages of the build. They've helped ensure a level of repeatable accuracy which would otherwise have been difficult to achieve.

Ian Kirkwood

On display

The completed model will be a feature display of the Dartmouth Museum's new Mayflower exhibition. The town will welcome thousands of visitors from around the world this summer. Events marking the 400th anniversary of this famous voyage, will generate significant tourism revenues in the UK.

A one tenth scale model of the Mayflower will be ready for commemorative events marking the 400th anniversary of the voyage of the Mayflower in 1620.

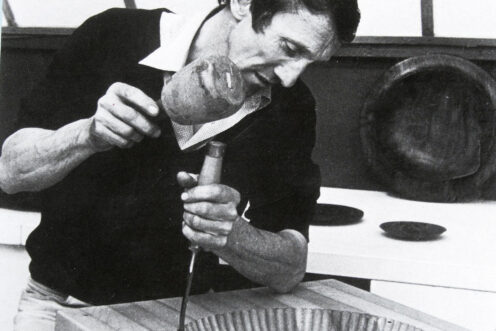

Main image shows Alan Peters' chest with silver inlay.

The Alan Peters Furniture Award is organised by Jeremy Broun in collaboration with The Woodworker magazine. Axminster is sponsoring this new award which celebrates the legacy of Alan Peters OBE, one of Britain’s most prominent furniture designer-makers of the late 20th century. At the same time, the award aims to encourage talent in the craft of furniture design and making.

The man behind the award and its history

Alan Peters OBE (1933-2009) was apprenticed to Edward Barnsley and directly linked to the English Arts and Crafts Movement. Therefore, he was hugely influential internationally in his practice, teaching and publications. His understanding of how wood behaves and the value of hand skill resulted in the creation of many timeless pieces. However, he also had a respect for moving tradition forward. Alan created affordable, durable, functional furniture, making an art of his craft in some of his subtle innovations.

Originally called ‘The Alan Peters Award for Excellence’, Jason Heap initiated it in 2010 and the award ran for eight years. Each year there were three winners, all of whom received free exhibition space at the annual furniture exhibition in Cheltenham. James Long's winning piece in 2011 appears in this article.

The competition

The competition is open to any woodworker who is resident in the UK and over the age of 18. Naturally, applicants should have a passion and talent for designing and making contemporary furniture. Applicants may submit up to two items of furniture that echo the philosophy of Alan Peters. Judging will be based on the appropriate use of wood, quality of workmanship, functionality and originality of design. Furthermore, applicants should be familiar with the work of Alan Peters prior to applying.

The 2020 award was postponed and the deadline for entry is now 14th March 2021. Therefore, applicants can submit their entries at any time up to this date. A fee of £20 per entry (with a maximum of two entries) applies.

The judging of furniture pieces will be in March with the online Award Ceremony broadcast in the second week of March. Subsequently, the winning pieces will be exhibited at The Wilson Gallery which is part of Cheltenham Art Gallery & Museum; the organisers will confirm these dates shortly.

How to enter

To download an application form please click here. The form is on the right hand side of the page. Applicants can make a payment securely via the website.

The judges

Jeremy Broun (organiser) – designer-maker and co-exhibitor with Alan Peters 1978-2002.

Andrew Lawton – designer-maker who worked with Alan Peters and on his last commission.

David Barron – maker of fine contemporary furniture and tool maker.

The prizes

First prize: £1,000 Axminster Tools & Machinery gift card

Second prize: £500 Triton Tools voucher

Third prize: £300 judges’ prize

For further information, please contact either the Editor of The Woodworker magazine Tegan Foley tegan.foley@mytimemedia.com or organiser Jeremy Broun jb@woodomain.com.

Website: woodomain.com/alanpetersaward

Instagram: @alan_peters_furniture_award

Main image shows Alan Peters’ chest with silver inlay. The Alan Peters Furniture Award is organised by Jeremy Broun in collaboration with The Woodworker magazine. Axminster is sponsoring this new award which celebrates the legacy of Alan Peters OBE, one of Britain’s most prominent furniture designer-makers of the late 20th century. At the same time, the award aims to encourage…

Jake Knight, Head Engineer here at Axminster Tools & Machinery, has become a ‘Young Pioneer’ and joined The Manufacturer Top 100. Jake received his award at a gala reception in Liverpool earlier this month.

The Manufacturer magazine's Top 100, in partnership with Cranfield University, is a showcase for the most inspiring individuals in industry. These individuals exemplify the enthusiasm and commitment present in modern manufacturing. Awardees come from all walks of UK industry, from the shop floor to the top level. Nominations for the 100 individuals came from customers, team members, their leaders or from those they lead. Therefore they are among the very best that UK manufacturing has to offer. Furthermore, the 100 are catalysts for change, striving for innovation, the newest technologies and pioneering business models. To sum up, they are the driving force behind the UK’s manufacturing industry.

On receiving the award Jake said:

It came as such a surprise to me both being nominated and then going on to win. I‘m thrilled to bits. I’m very happy that hard work is recognised and it motivates me even more. Another positive outcome is that I can now nominate two people for next year’s awards, which is really exciting.

Trustpilot

Axminster Tools enjoyed further success when the company discovered that it now ranks number 1 out of 64 in the category “Tool Shop” on Trustpilot. Trustpilot.com is a consumer review website which hosts reviews of businesses worldwide. Customer Service Manager Helen Terry said:

This is a significant achievement and the result of everyone’s hard work and contribution. Customers have also commented on our catalogue, the quality of the products we sell and the packaging. It is clear from these reviews that there is not just one aspect of our service which has put us in the top spot, but it is a result of fantastic teamwork.

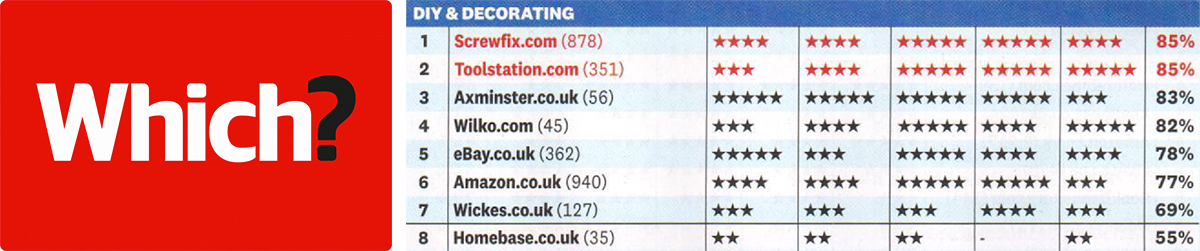

Which? magazine

What’s more, in a survey for Which?, Axminster came third, scoring 83% in the Top 10 for the DIY and Decorating category including a 5 star rating for range, quality, ease of ordering and practicality of delivery. Axminster felt this was a big achievement, since the company doesn't offer as wide a selection of this type of product as the two companies in first and second place.

An impressed shopper told the magazine:

Its (Axminster Tools’) customer service is 10 out of 10. I buy from Axminster with confidence.

The same shopper, who has attended courses at Axminster’s Skill Centre, added: “(It’s) not really a fair comparison in that Screwfix are good for general building supplies and Toolstation merely a catalogue house”. Managing Director Alan Styles commented: "He’s absolutely correct. I believe to score well in the category of DIY and Decorating is great recognition. If it was purely on tools and machinery where would we be? The Which? article recognises everyone's hard work, particularly those in customer service and retail who make sure our service is 10 out of 10."

Jake Knight, Head Engineer here at Axminster Tools & Machinery, has become a ‘Young Pioneer’ and joined The Manufacturer Top 100. Jake received his award at a gala reception in Liverpool earlier this month. The Manufacturer magazine’s Top 100, in partnership with Cranfield University, is a showcase for the most inspiring individuals in industry. These individuals exemplify the enthusiasm and…

Main image: Huw Evans and his Concertina Collection

The Young Furniture Makers exhibition returned to the City of London for one day only on Wednesday 9th October 2019. Consequently, the event gave industry the opportunity to connect with today's young, creative talent. These young people will be the designer-makers of the future, looking to make an impact on the sector. What's more, around 1,000 visitors came to the exhibition making it the most successful to date. In line with tradition, The Furniture Makers’ Company organised the exhibition. And this year Axminster Tools & Machinery was the main sponsor with a number of supporting sponsors.

Similar to previous years, the event featured the very best furniture and furnishing design talent from around the UK. Entries came from GCSE and A level students, BA and MA graduates, and young professionals. As a result, some 150 of the UK’s freshest designers exhibited furniture and lighting at Furniture Makers’ Hall and the Dutch Church in Austin Friars, London.

Award winners

This year’s award winners were as follows:

| Blum Best in Show – Huw Evans of Plymouth University for Concertina Collection |

| Bespoke Award First Place – Matthew Hensby of Building Crafts College for Kent Stick Chair |

| Design Award First Place – Nina Naveršnik of Birmingham City University for Lucy Light |

| Innovation Award First Place – Huw Evans of Plymouth University for Concertina Collection |

| School Design First Place – Millie Harper of Ipswich High School for Egg Cot |

Huw Evans, as winner of the Blum Best in Show prize, receives an all-expenses paid trip to the state-of-the-art Blum factory in Austria. This prize goes to a student in higher or further education who has produced the most outstanding piece of work. Huw said: "I want to say a huge thank you to The Furniture Makers’ Company for granting me the opportunity to exhibit alongside such a pool of talent. I’m honoured to have received such a positive response from both my peers and the visitors at the exhibition."

Paul von der Heyde, new chairman of Axminster Tools and Machinery, made the following comment: "The show presented a wonderful picture of the creativity and talent of the next generation of furniture makers. In addition, the enormous attendance and energy at the awards session was inspirational. To sum up, it was a thrill to be associated with such a vibrant and inspiring event."

Finally, ten outstanding pieces from the exhibition will be on display at the 2020 Furniture Show (19-22 January, NEC Birmingham). This will give the winners the opportunity to expose their work to 22,000+ visitors and build high level contacts.

Main image: Huw Evans and his Concertina Collection The Young Furniture Makers exhibition returned to the City of London for one day only on Wednesday 9th October 2019. Consequently, the event gave industry the opportunity to connect with today’s young, creative talent. These young people will be the designer-makers of the future, looking to make an impact on the sector….

Axminster is supporting mental health awareness and has organised a week of activities for staff to take part in. Such activities range from mindful exercises to a 10,000 step challenge. Plus, staff are encouraged to give each other mutual appreciation to engender a feeling of mental and emotional wellbeing. Furthermore, to support this activity Managing Director Alan Styles has signed the ‘Time to Change Employer Pledge’. This is a 12-month employer action plan committed to changing the way people think and act about mental health in the workplace.

Time to change

‘Time to Change’ is the charity leading mental health awareness. Also, it is the force behind the ‘Pledge’ and quotes the following statistics on its website:

- Conditions such as anxiety, depression and stress affect one in four British workers every year;

- Mental ill-health is the leading cause of sickness absence in the UK;

- Nine out of ten people who experience mental health problems say they face stigma and discrimination which can be even more damaging;

- 300,000 people leave their place of work each year due to poor mental health.

The need to eradicate stigma and discrimination

Axminster's HR team have become increasingly aware of the potential problems, which can arise through poor mental health, including stigma and discrimination. Therefore, the company is carrying out a number of initiatives to help tackle this significant issue.

"We are already working with the Axminster-based charity Arc, which specialises in recovery through counselling. Two Arc counsellors are available if staff wish to attend workplace counselling sessions. Most managers have attended a training programme about mental health which Arc have provided and we are offering all staff mental health workshops if they wish to attend," explained HR Director Jane Boulton.

As a family company, we want to help encourage openness about mental health and to erase the stigma around this. Staff should feel able to disclose their personal experiences and feel more confident about making managers or colleagues aware of their experience.

Axminster is supporting mental health awareness and has organised a week of activities for staff to take part in. Such activities range from mindful exercises to a 10,000 step challenge. Plus, staff are encouraged to give each other mutual appreciation to engender a feeling of mental and emotional wellbeing. Furthermore, to support this activity Managing Director Alan Styles has signed…

Cardiff Racing competed in Formula Student at Silverstone over the weekend of 19-21 July in the car they launched only last month.

Silverstone yields some positive results

Overall the team came 18th out of a total of 81 teams and were pleased with the car’s performance. A spokesperson for the team said:

We’re happy with our statics results, coming 12th in Design and 16th in Business! Dynamics also went well, and we were fourth in Acceleration. Unfortunately, due to an unscheduled mass reduction during the Skid-Pad, we had to remove our front wing. However, spirits are high, the car is proving reliable, and we’re looking forward to endurance

Dramatically, the car hit a cone during the Skid-Pad challenge resulting in the team having to remove the front wing.

A car named Cristal

The car named Cristal is a play on CR15tal (the latest model number) and because crystal is the 15th wedding anniversary gift, so the team felt the name worked well. CR15 or Cristal has a full aluminium monocoque chassis; previous cars have had the half space frame and half honeycomb design. Interestingly, an earlier version of the aluminium monocoque chassis was first used in the 1962 Lotus 25 Formula 1 race car.

This year the team had aimed to build the car as small and light as possible, thereby pushing its limits.

We achieved a weight of 205 kilos full wet which is good for the type of engine we use. We have designed a side diffuser to increase the car’s downforce. The aid of new dampers with more adjustability will also help the setup

Lee Trehearne, Cardiff University’s automotive engineer

The team put in a lot of hours to work on the car, with one student saying he had put in an extra 15-20 hours a week, with weekends on top to ensure the car was ready.

Success and setbacks in the Netherlands

Cardiff Racing also competed in the Netherlands earlier in July with mixed fortunes. Although they were the top UK team in the static competition, the team subsequently had a few problems with the car’s reliability and competition timings, areas they then worked on before competing at Silverstone.

This year’s drivers in both competitions were Ben Chappell, Louis Crozier, Matt Haines and Guglielmo Sonnino Sorisio. Ben Mason was head of chassis, Ben Chappell head of aerodynamics and Louis Crozier head of suspension.

Axminster continues to support Cardiff Racing with the loan of iKX3 CNC milling machine. Plus, the Cardiff store has given the team a benchtop pillar drill. To quote one of the team:

"Axminster have been the best help, we wouldn't have been able to achieve what we have without them

Cardiff Racing competed in Formula Student at Silverstone over the weekend of 19-21 July in the car they launched only last month. Silverstone yields some positive results Overall the team came 18th out of a total of 81 teams and were pleased with the car’s performance. A spokesperson for the team said: This year the team had aimed to build…

Steady progress is being made building the 1/10 scale model of the Mayflower at a special workshop at the Britannia Royal Naval College in Dartmouth. The bulk of the tools and machines for the project have been provided by Axminster Tools & Machinery and their supply partners.

Steady progress is being made building the 1/10 scale model of the Mayflower at a special workshop at the Britannia Royal Naval College in Dartmouth. The bulk of the tools and machines for the project have been provided by Axminster Tools & Machinery and their supply partners.

The model of the famous ship which carried the first pilgrims to the New World in 1620 is being built by Captain Ian Kirkwood with help from volunteers and students on behalf of the Dartmouth Museum. Despite technical challenges, the model is on target for completion in November, when the first commemorative events marking the epic voyage commence.

One-time officer, yacht builder and shipwright, Ian admits that the task has been 'daunting at times'.

Everything is one-tenth smaller than what I'm used to. You need smaller tools, greater dexterity and more patience. And there’s so much less margin of error. It’s a world of high precision where small inaccuracies are soon exaggerated in the build.

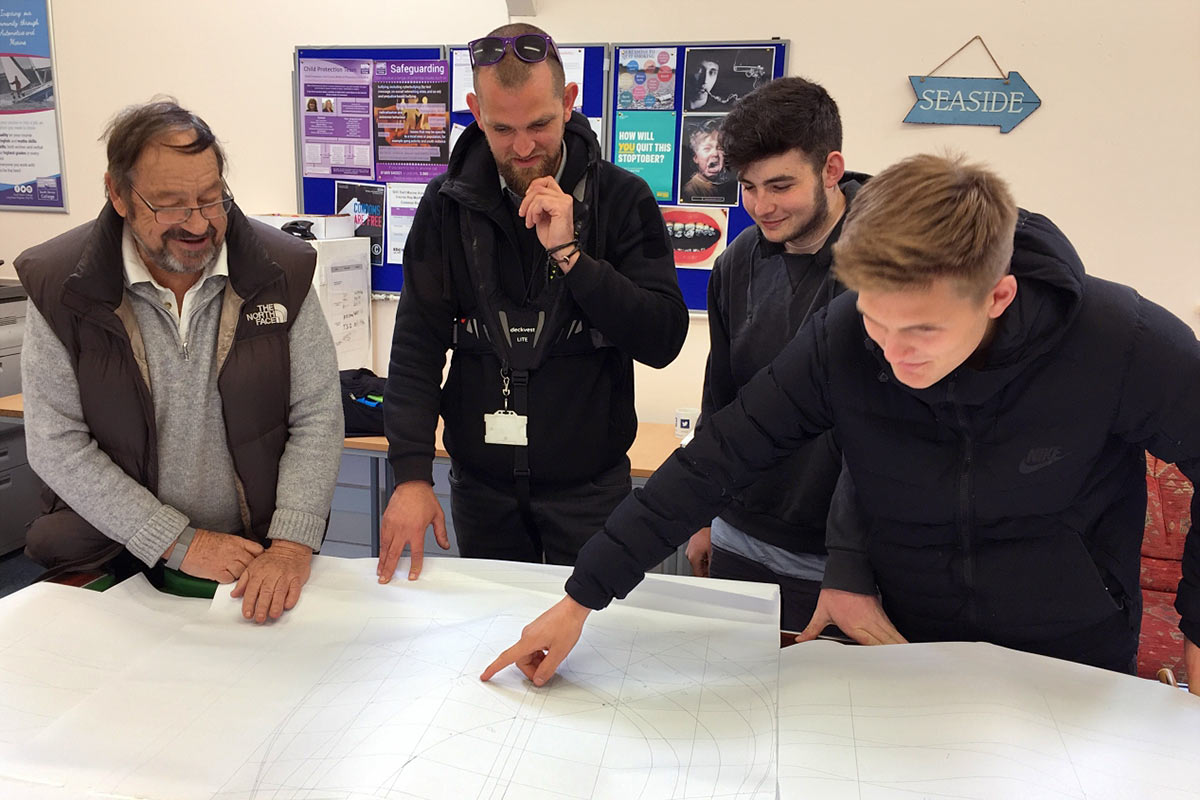

Along with a handful of volunteers, Ian is being assisted by students of the South Devon Marine Academy, who have been helping with the painstaking laminations to make up all the main structural components. Although no blueprints of the Mayflower can be reliably sourced, detailed plans of a ship believed to be very similar to the Mayflower have been provided by the Massachusetts Institute of Technology (MIT).

With the hull framing complete, the latest phase has been building and laying the decks, with the gun deck and quarter deck recently fitted. The model is split lengthways, to show detail of construction and to reveal the interior of the hull which was extremely confined for the 92 pilgrims and 30 crew of the Mayflower.

"A specialist model builder is being brought in to provide detailed fittings, furniture and stores which will provide a fascinating view in miniature of life below decks. The ship will also be fitted with masts, sails and rigging which is going to require specialist knowledge

The model build has attracted a good deal of public and media attention, and has featured on regional BBC and ITV television and radio news programmes.

At the conclusion of a year's 'Mayflower 400' commemorations in 2020, the Mayflower model will become a permanent display in Dartmouth Museum, with accreditation to Axminster Tools & Machinery and their supply partners.

A boost for regional and national tourism

The Mayflower model will be a feature attraction within the many special 'Mayflower 400' events planned from November 2019 to November 2020. These events will explore all aspects of the Mayflower history and legacy and reflect core themes of imagination, humanity, freedom and future. The programme of cultural and heritage events is expected to attract over a million visitors to the UK and generate revenues of over £400 million for business at the 11 Mayflower national trail destinations.

Four nations - the UK, the United States, the Netherlands and Denmark - will commemorate the sailing of the Mayflower in 1620 from England to the New World.

Machines and tools provided to the project by Axminster and supply partners include:

-

PROXXON AH 80 Surface PlanerFrom £375.58 £312.98

-

PROXXON DS 460 2 Speed Scroll SawFrom £455.98 £379.98

-

PROXXON DH 40 ThicknesserFrom £565.98 £471.65

-

Tormek T-4 Original Sharpening SystemFrom £439.98 £366.65

-

UJK Professional Router TableFrom £899.98 £749.98

...as well as a selection of Lie-Nielsen hand tools, Aries Dust Extraction and Duct Fixes.

Steady progress is being made building the 1/10 scale model of the Mayflower at a special workshop at the Britannia Royal Naval College in Dartmouth. The bulk of the tools and machines for the project have been provided by Axminster Tools & Machinery and their supply partners. The model of the famous ship which carried the first pilgrims to the…

Staff at Axminster Tools & Machinery recently picked up an award at the Devon Sports Awards. The company won the award for ‘Business Contribution to Staff Well Being through Sporting Activity’. The award criteria related to the achievements for the sporting year to 31st March 2019.

Keeping fit and staying healthy

Axminster is keen to promote a healthy lifestyle for all of its employees. This combines work-life balance, healthy eating and physical activities. To this end, the company has encouraged and financially supported a range of lunchtime and after-work sports and activities. These include netball, football, HIIT (high-intensity interval training) sessions and most recently a lunchtime spinning class at the local LED sports centre.

Devon Sports Awards

The awards evening took place at Sandy Park the home of Premiership rugby team Exeter Chiefs. Jenny Walrond, BBC Spotlight’s Health Correspondent, compèred the evening and Rob Baxter, director of rugby at Exeter Chiefs, held a Q&A session. After the presentation of the awards, BBC Radio Devon’s James Vickery interviewed some of the winners which included one with Axminster’s Buying & Product Manager, Laurie Forino, who said:

We came here tonight never imagining we would win an award, but are thrilled that we have. Whether it’s netball, football, spinning, having a HIIT session or a lunchtime walk, many of us enjoy sport and taking part in some of the activities supported by the company. It’s fantastic to win an award for something we really enjoy.

Five-a-side team claim victory

More sporting success was enjoyed by Axminster's five-a-side team. They were one of 13 teams competing in the Herman Miller Cup which The Furniture Makers’ Company organised. On Sunday 30th June the team travelled to the Lucozade Powerleague Football Centre in Coventry to play in the tournament. Kick-off was at 1pm and play was fast and furious. After winning several games, our team found themselves in the final facing bed manufacturer Hypnos. However, at full-time the score was 2-2 meaning the match would have to be decided in a penalty shoot-out. The game came down to the wire, with a heroic save from goalkeeper Joe Berry and a final goal from Billy Long, resulting in our team winning the game 3-2 on penalties.

Dids Macdonald OBE, Master of The Furniture Makers’ Company, said:

The Herman Miller Cup was fabulous, with more than 100 keen footballers taking part, and what an amazing final between Axminster and Hypnos. However, where were all the women players? Next year, I hope! We’d like to thank our sponsor, Herman Miller, for their tremendous support in helping make this wonderful event possible.

The event raised a record £4,500 for the charity.

Staff at Axminster Tools & Machinery recently picked up an award at the Devon Sports Awards. The company won the award for ‘Business Contribution to Staff Well Being through Sporting Activity’. The award criteria related to the achievements for the sporting year to 31st March 2019. Keeping fit and staying healthy Axminster is keen to promote a healthy lifestyle for…

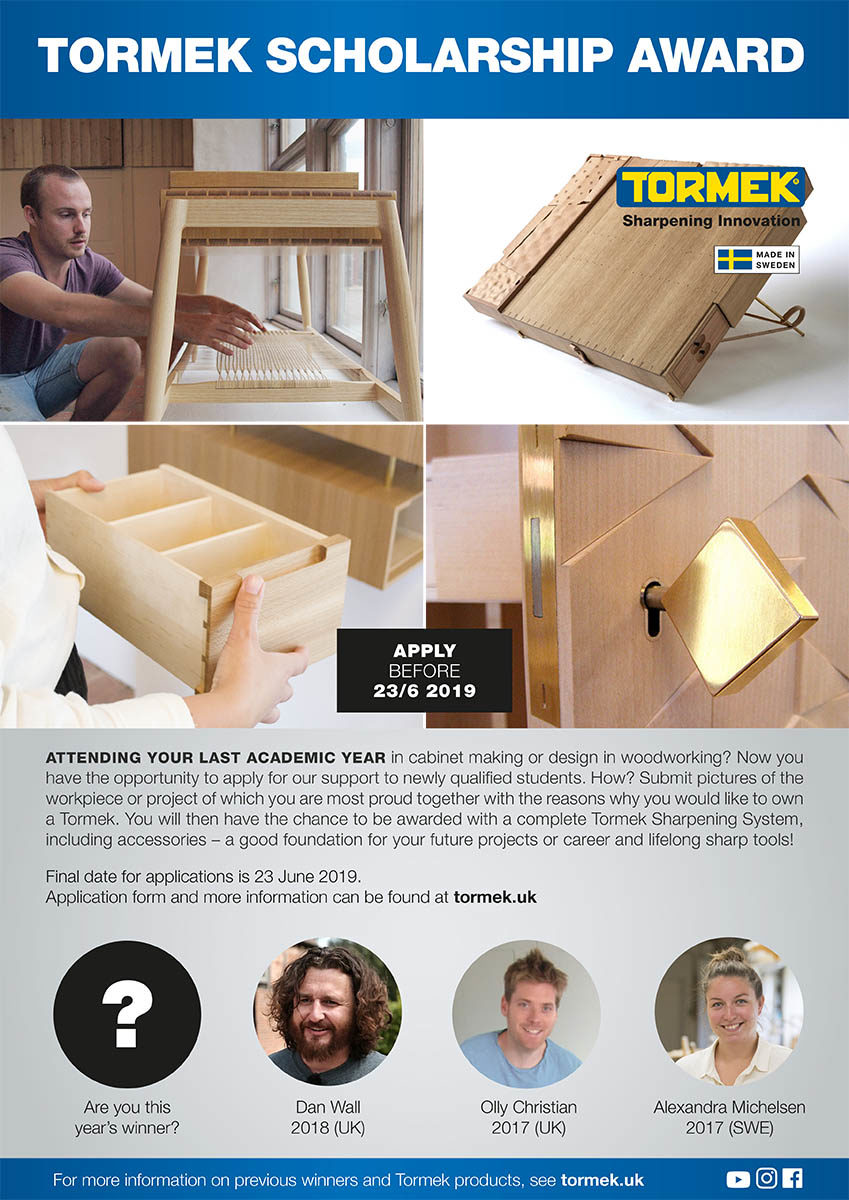

The Tormek Scholarship Award (UK) is presented each year, since 2013, to a final year student attending a furniture/cabinet design and make woodworking course. Last year Dan Wall from Worcester received the award and in 2017 it went to Olly Christian from Bristol. In addition to the accolade of the award, the winner receives a Tormek Wet Sharpening System. Previous winners admit this has proved to be invaluable, encouraging them to aspire to higher professional qualifications and invest time in their woodwork.

How to enter

Simply submit images of your piece of work together with your reasons for wanting to own a Tormek machine. You must be the maker of the piece and have used a Tormek during the making process. Tormek will publish the results on their website and include a short interview with the winner.

Closing date

The final date for applications is 23 June 2019. You will find more information and the application form on the Tormek website.

The Tormek Scholarship Award (UK) is presented each year, since 2013, to a final year student attending a furniture/cabinet design and make woodworking course. Last year Dan Wall from Worcester received the award and in 2017 it went to Olly Christian from Bristol. In addition to the accolade of the award, the winner receives a Tormek Wet Sharpening System. Previous…

Don’t miss us at this year’s Midlands Woodworking Show at the Newark Showground in Nottinghamshire.

New Craft machines

At the show, we will be reacquainting visitors with our new Craft range of machinery, which some of you may have seen at the Harrogate Show last November. The range is perfect for the discerning home user and those dedicated, creative souls who literally spend hours in pursuit of refining their craft. Therefore, within the range, you will find new lathes, bandsaws, scroll saws, sanders, grinders and a table saw. Furthermore, these machines are affordable and come with enhanced features not normally found on machines at this level.

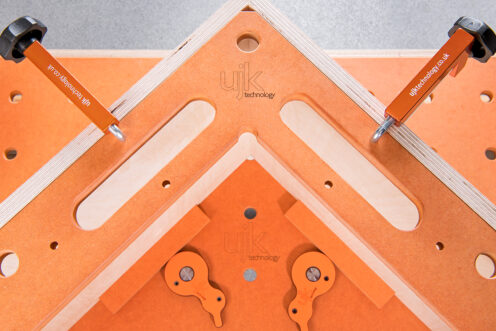

Axminster Rider and UJK Technology

As well as Craft, we will be focusing on two of our best known and well loved brands: Axminster Rider and UJK Technology, both of which are now well established. Axminster Rider planes represent a good standard in traditional, quality plane manufacture. Axminster has designed and developed every plane and they offer great value. Other Rider hand tools will be available at the show. UJK Technology products are also designed and manufactured in-house at Axminster. Covering routing, measuring and wood jointing, UJK products are highly innovative, accurate and reliable.

The Axminster team

Some of our most experienced staff will be looking after these tools and machines, demonstrating how they can enhance the user’s craft or hobby. Rider planes will be in the capable hands of Matt Estlea and Dean Maddison. (Matt is now lecturing at Rycotewood, but used to work at our Basingstoke store.) Steven Taylor and Scott Peach will explain all you need to know about UJK Technology. And the new Craft range will have Stephan Parker and Simon Trinkwon taking care of it. As with the Harrogate Show, Skill Centre Manager Craig Steele will head up the team.

So, don’t hesitate to come and see us. As always, our friendly team will be available to answer any of your woodworking or tool and machinery related questions and provide guidance on purchase and use.

For more information about the Midlands Woodworking Show visit the show's website.

Don’t miss us at this year’s Midlands Woodworking Show at the Newark Showground in Nottinghamshire. New Craft machines At the show, we will be reacquainting visitors with our new Craft range of machinery, which some of you may have seen at the Harrogate Show last November. The range is perfect for the discerning home user and those dedicated, creative souls…

For the past 18 months Axminster Tools & Machinery has been working with and supporting the Sylva Foundation and Wood Centre in Long Wittenham, Oxfordshire.

Earlier this year on 16th January, Sylva opened its new teaching barn. This was the next step of the Foundation’s vision to deliver education and training at the Sylva Wood School. The design of the building allows it to easily transform from workshop to classroom. Therefore, Sylva will be able to host seminars, presentations and events, together with a wide range of practical courses.

Representatives from the furniture industry attended the opening event. Guests included Dr Tony Smart (past Master) and Dids MacDonald (Senior Warden) from the Furniture Makers’ Company; designer-makers Richard Williams and Philip Koomen, plus representatives from Williams & Hand and Ercol.

New Head of Wood School

Joseph Bray, Sylva's new Head of Wood School, shared his thoughts on the future of wood in the education sector. Here Joe focuses on the opportunities to deliver excellence in education and business enterprise.

“School classes have changed from woodwork to much broader D&T and over the past 10 years the decline in entries to GCSE has reduced by well over 50%. The emphasis of these courses has significantly moved away from making! Colleges offering vocational furniture training can almost be counted on one hand and university level craft programmes have declined significantly some closing workshops and some closing all together. Often graduates are pushed out into the world with varying levels of support and guidance.

“An exception to the rule is our close neighbour Rycotewood in Oxford. We hope to enhance our close relationship continuing to work closely with staff, students and graduates."

Workshop and skills training

Joe continued to say: “The future can feel bleak. However, we exist outside the formal education system. As a creative and flexible organisation we are able to offer a range of programmes that will plug some of the gaps. We plan to build a schools programme for those unable to access making on the school curriculum. We will provide workshops and skills training to students who cannot access this at college or university and we will continue the excellent work already started in providing support for graduates within the community of creative enterprises that make up our site.”

Joe is also part way through an inspiring Churchill Fellowship, travelling to world-renowned institutions that deliver furniture craft education in USA and Europe. He is investigating how they continue to support students to learn craft skills in light of the challenges within the education sector and how they support students after graduation. This experience is especially helpful at this stage of the development of the Sylva Wood School.

Sylva is currently running a programme of weekend courses using external tutors. Moving forward, the school plans to launch more courses in the summer and beyond.

For the past 18 months Axminster Tools & Machinery has been working with and supporting the Sylva Foundation and Wood Centre in Long Wittenham, Oxfordshire. Earlier this year on 16th January, Sylva opened its new teaching barn. This was the next step of the Foundation’s vision to deliver education and training at the Sylva Wood School. The design of the…

The Furniture Makers’ Company held its annual one-day Young Furniture Makers exhibition last month, showcasing an impressive level of design talent among participating students. Axminster Tools & Machinery was one of the sponsors.

The exhibition displayed around 90 pieces of furniture and lighting from GCSE and A Level students through to BA and MA graduates. As a result, it was one of the most exciting displays in the exhibition’s history.

The sponsors

Held in the Dutch Church and Furniture Makers’ Hall in Austin Friars (London), the Young Furniture Makers exhibition is free for students to take part in. Accordingly, it provides the next generation of designers and makers an invaluable opportunity to present their designs to key members of the furnishing and design sector and the exhibition's sponsors. Other sponsors this year were Bensons for Beds, Harveys Furniture and The Furniture Ombudsman.

The judges

During the evening of the event, Master of the Furniture Makers’ Company Hayden Davies presented this year’s awards and thanked the sponsors. A panel of judges had already assessed the pieces earlier in the day. This year’s judges were Anthony Bailey – editor of Woodworking Crafts magazine; Steven Minghella – retail sales manager at Timothy Oulton; Rupert Senior – multi award winning designer maker; Peter Sharratt – technical support advisor at Blum; and Alan Styles – managing director of Axminster.

The winners

The winners of the awards were:

- The Bespoke Award, sponsored by Festool – Beatrix Bray for the Fluctuare Table

- The Design Award, sponsored by Crofts & Assinder – Lewis Small for Wilf Floor Lamp

- The Innovation Award, sponsored by Knightsbridge – Matt Hill for the Array Table

- The National School Prize – Brodie Haward for the Radioactive Bench

- The Blum Best in Show Prize – Harriet Speed for Corkey’s Cabinet

- The Timothy Oulton Best in Show Prize – Mac Collins for the Iklwa Chair

Axminster MD Alan Styles said: “We are proud to support the Young Furniture Makers exhibition for the fourth year in a row. The event is a great way for students, education and industry to network. The work by the Furniture Makers’ Company and the many individuals who give their time is making a notable difference. Axminster is focused on developing products and services to suit its many customers. Our association with the Young Furniture Makers and The Furniture Makers’ Company gives us a great insight in which to develop what we do. So we feel privileged to give back.”

It was a massive surprise and I am really grateful for the opportunity to go out to Hong Kong with Charlie Oulton and the team. It was a great evening surrounded by lovely people, both new and established, in the furniture industry.

Mac Collins (winner of the Timothy Oulton Best in Show Prize)

The Furniture Makers’ Company held its annual one-day Young Furniture Makers exhibition last month, showcasing an impressive level of design talent among participating students. Axminster Tools & Machinery was one of the sponsors. The exhibition displayed around 90 pieces of furniture and lighting from GCSE and A Level students through to BA and MA graduates. As a result, it was…

His Royal Highness The Duke of Gloucester recently visited Exeter College’s new £3 million Advanced Engineering Centre at Exeter College and met with key industry partners.

During a tour of the centre, The Duke was able to find out more about both students and staff, and how they benefit from the centre, which is a leading hub of excellence for virtual welding and robotics.

Exeter College Principal and Chief Executive John Laramy briefed His Royal Highness about the ethos of the college and the high standard of training delivered within the facilities.

During the visit, The Duke also met with employer representatives from Axminster Tools & Machinery, Arconic and Hepco Motion. Thus, demonstrating there are strong links and collaboration between the college and its industry partners. Axminster were key in the supply of engineering machinery for the machine shops and advanced machining workshop.

Alan Styles, MD of Axminster Tools said:

It was a proud moment to meet The Duke of Gloucester. We are keen to encourage and support Exeter College in any way we can. We’ve worked very closely with the College for several years by sending apprentices, providing advice and supplying machines to the Advanced Engineering Centre which students are now able to take advantage of. We are delighted to have been involved in the setting up of such a fantastic facility here in the South West – a facility which makes Exeter College one of the best in the UK for engineering disciplines. The machines and equipment together with the high quality teaching will give Exeter College students a head start when it comes to future employment.

The new facility is an extension of Exeter College's Technology Centre. Situated on the edge of Exeter, it is meeting the growing demand regionally for skills in engineering, robotics and automated manufacturing.

His Royal Highness The Duke of Gloucester recently visited Exeter College’s new £3 million Advanced Engineering Centre at Exeter College and met with key industry partners. During a tour of the centre, The Duke was able to find out more about both students and staff, and how they benefit from the centre, which is a leading hub of excellence for…

It’s amazing how quickly the North of England Woodworking & Power Tool Show comes around each year and now it’s only three weeks away.

Commonly known as the 'Harrogate Show', the show is now under new ownership. Publishing company My Time Media acquired it almost a year ago. However, visitors are unlikely to notice much of a difference, as the show’s organiser Tony Cox is still very much in the frame.

New machinery ranges

At the show Axminster will be showcasing the new Trade machinery. Furthermore, the Harrogate Show will be the launch pad for many of the machines in the new Craft range. The Craft range comprises quality machines designed to meet the demands of serious hobbyists and deliver an exceptional, dependable performance. Read this article for more information about the Craft range .

New demonstrators

In addition to the Axminster machinery ranges, you will be able to see many other exclusive brands on the stand. These include Axminster Rider, UJK Technology, Arbortech, Leigh, Tormek and Veritas. Among our guest demonstrators will be inventor and woodworker Peter Parfitt and a representative from Help for Heroes who will be woodturning. This year we will be welcoming Roger Benton, well known in the USA for demonstrating Lie-Nielsen tools. Plus, Axminster's Product Development Director Ian Styles will be putting the new Ultimate Edge sharpening system through its paces.

Also, this year we are pleased to announce that Phil Irons will be demonstrating the New Zealand brand Woodcut Tools on stand 189. Woodcut is famous for the Bowlsaver MAX3 and Bowl Coring System, tools which allow the user to produce several bowls from a single blank of wood.

So, join us on our stands 45, 140 and 157, to meet our team and enjoy the demonstrations we will be putting on.

Message from the organisers

The North of England Woodworking & Power Tool Show is now in its 26th year. It is the largest and most established show of its kind in the UK

“There are over 90 exhibitors including all of the top tool and machinery companies, as well as more than 50 of the UK’s leading demonstrators taking part throughout all three days. Demonstrations will cover turning, carving, furniture making, CNC machinery, guitar making, boat building, spoon carving, scroll sawing, chair making and much, much more. The show will be a great day out for the thousands of visitors that attend every year.”

It’s amazing how quickly the North of England Woodworking & Power Tool Show comes around each year and now it’s only three weeks away. Commonly known as the ‘Harrogate Show’, the show is now under new ownership. Publishing company My Time Media acquired it almost a year ago. However, visitors are unlikely to notice much of a difference, as the…

It was a cool and blustery autumnal day on Friday 21st September when Axminster Tools & Machinery opened its doors to the public, welcoming over 200 visitors to HQ on Weycroft Avenue in Axminster.

Well known faces

Visitors were able to experience around 40 demonstrations and get hands-on with many tools and machines. Among the demonstrators were well known faces such as Robert Ingham - distinguished maker of collectable boxes and unique furniture pieces; Peter Parfitt - inventor of the UJK Parf Guide System and Parf Super Dog; Matt Estlea - talented young woodworker and YouTube star, and Colwin Way - international woodturner.

A variety of demos

HQ folk and many staff from all of Axminster’s eight stores took part, showing their expertise and woodworking skills. Some of the more quirky demonstrations from Axminster staff included Joe Berry with his cricket bat shaping. Also, Wayne Asher ran the ‘Hard Point Challenge’. The challenge was to cut through a piece of 2”x4” in the quickest time; the prize was a set of three Axcaliber saws. Plus, product development director Ian Styles gave a preview of the ‘Ultimate Edge’ - a new sharpening product launching soon. In addition, Wentworth Timber, who supply all the Axminster stores, were present as were UKMSA (Men’s Sheds Association) displaying the kinds of things they make (local Axminster stores work closely with local ‘shedders’)

Guided tours

Approximately 160 visitors signed up for the guided tour around the site. An Axminster director led each tour, taking visitors to the engineering facility where woodturning chucks and accessories, bandsaw blades and many products in the UJK Technology range are manufactured. Other points of interest on the tour route were the Skill Centre and warehouse which was fully operational on the day.

To keep warm, visitors were able to take advantage of the free tea, coffee and biscuits on offer. What's more, to add to the feeling of warmth, Axminster offered a 10% discount throughout the day.

It’s been a while since we had an event here at HQ, but I think the day has gone pretty well. I led some of the tours and have had some very enlightening comments and questions from visitors. And one of the most positive pieces of feedback is how pleased our customers are to see the return of the Axminster catalogue

Alan Styles (Managing Director)

It was a cool and blustery autumnal day on Friday 21st September when Axminster Tools & Machinery opened its doors to the public, welcoming over 200 visitors to HQ on Weycroft Avenue in Axminster. Well known faces Visitors were able to experience around 40 demonstrations and get hands-on with many tools and machines. Among the demonstrators were well known faces…

The W Exhibition is just around the corner and will be happening at the NEC for four days from 30 September to 3 October. Now under the wing of events company Angus Montgomery, the event has been running in one guise or another for over 40 years. Taking place every two years, the W Exhibition offers the UK’s furniture and joinery manufacturers the chance to meet and network with other industry players and see what’s new on the market.

New Axminster Trade machines

Once again, Axminster will be exhibiting, using the event as a platform to showcase the recently upgraded trade rated range of woodworking machinery. As a result, five new machines have joined the Axminster Trade range: a bandsaw, table saw, two spindle moulders and a dust processor. These machines are aimed at bespoke furniture and joinery makers, small scale kitchen/bathroom producers and keen home woodworkers wanting a higher spec machine.

The five new machines were chosen for their uniqueness or build quality. The Gyro dust processor is compact and needs no assembly. It is built with ground-breaking axial centrifugation technology. The new bandsaw is designed to be one of the best 350mm bandsaws on the market with many exclusive features. The table saw will take some of Axminster’s unique accessories such as parts from the UJK Technology range. There are two spindle moulders: deluxe and CNC. The CNC has a Siemens control system, allowing you to mould profiles with optimum accuracy and achieve perfect results. The deluxe comes as a 230V and 415V version.

In addition, visitors will be able to watch Lamello jointing in action, and learn about the original and inventive range of UJK Technology products.

Elements of Innovation

This is an important show for us where we will be exhibiting our new and exciting high-end woodworking machinery. We have also entered a product into the Elements of Innovation awards running at the W Exhibition. The criteria stated that the product must have come to market since W Exhibition 2016. Also, the product should be brand new, standout and innovative. For us there was only one contender: the UJK Parf Super Dog which we launched earlier this year. Wish us luck!

Darran McLeod (Sales Director)

Get your tickets!

The W Exhibition runs at the NEC Birmingham from Sunday 30 September to Wednesday 3 October (Sunday 10.30am-5pm; Monday and Tuesday 9.30am-5pm; Wednesday 9.30am-4pm). Please visit the exhibition's website to register for your free entry ticket.

The W Exhibition is just around the corner and will be happening at the NEC for four days from 30 September to 3 October. Now under the wing of events company Angus Montgomery, the event has been running in one guise or another for over 40 years. Taking place every two years, the W Exhibition offers the UK’s furniture and…

Drama, passion and excitement were all ingredients present at the Formula Student (FS) event held at Silverstone from 11-15 July. This year marks the 20th anniversary of the competition.

For the past two years, Axminster has given support to Cardiff Racing (part of Cardiff University) lending the team an iKX3 CNC milling machine. The iKX3 has proved invaluable for the manufacture of a number of specially designed components.

Earlier this year, Axminster began to give support to Newcastle Racing which is part of Newcastle University. The team now have full use of a KC6S lathe and KX3S mill.

How did they get on?

Both Cardiff Racing and Newcastle Racing built new cars for the Formula Student Silverstone event this year. In 2017 Cardiff were the first British team to win the annual Formula Student Silverstone event. So, how did both teams get on this year?

FSUK is over for another year, a big thanks to all of our sponsors and supporters for making it all possible! We had a really tough weekend with some things not going quite right for us, but we still finished 13th overall and we will come back much stronger in FSCzech.

Cardiff Racing tweet

Clutch issues

Finalising the design of the Cardiff car was late this year; the first test date was not until the last week of June.

At the event the automatic clutch failed. Therefore, the driver had to resort to the hand clutch, which was something new for the driver to get to grips with. However, the car completed every event at Silverstone and there were no problems with the engine, temperature and reliability. Further tests are now being carried out before both car and team go to the Czech Republic to compete.

The Axminster iKX3 mill again this year has been a life saver. It’s been manufacturing parts all year, the only limiting factor being the physical size of the machining area. Some of the larger parts I had to make on the bigger machines. I would say the iKX3 has made over 60% of the machine parts on the car using a solid cam machining software.

Lee Treherne (Cardiff University automotive engineer)

Going electric

The Newcastle team have been focusing on the development and build of an electric car. Although they attended the Silverstone meet, they were there to promote their new electric car and did not compete. However, they were absolutely delighted to be awarded fourth place for design - an achievement which was totally unexpected.

Formula Student is the world’s largest student engineering design competition. FSUK attracts entries from around the world, including USA, Australia, India, Canada and the Far East, as well as many European teams.

Entrants compete to design, build and race a formula racing car, providing undergraduates with invaluable experience before they begin their engineering career.

FS showcases the best and brightest mechanical engineering talent, with graduates regularly filling roles in organisations such as Ferrari, Williams Grand Prix Engineering, Mercedes AMG High Performance Powertrains, ExxonMobil and Bosch.

As a spectator experience, FS presents the opportunity to get up close and personal with some phenomenal combustion engines and electric single seater racing cars built entirely by students who just might go on to design, build or race the F1 cars of the future.

Former F1 champion attends FS

One of this year’s high profile speakers was former F1 champion Jenson Button who said:

I’m here today to help inspire the next generation of engineers and to highlight the importance of support provided by Santander Universities. Formula Student is massive and it’s great to see over a hundred teams here competing. Some of the cars that they engineered with and the ideas that they have come up with are outstanding.

Drama, passion and excitement were all ingredients present at the Formula Student (FS) event held at Silverstone from 11-15 July. This year marks the 20th anniversary of the competition. For the past two years, Axminster has given support to Cardiff Racing (part of Cardiff University) lending the team an iKX3 CNC milling machine. The iKX3 has proved invaluable for the…

As part of international celebrations marking the 400th anniversary of the Mayflower’s voyage to the New World in 1620, Axminster has provided a range of tools and machines to help build a 3 metre 1/10th scale replica of the Mayflower in Dartmouth. These include an Axminster Hobby Series Table Saw, UJK Technology Router Table and Trend Router, a Proxxon Table Saw, Proxxon Surface Planer and Festool Cordless Drill Driver.

Renowned North American supply partner to Axminster Tools & Machinery, Lie-Nielsen, have also agreed to sponsor a number of hand tools including planes and chisels, while Tormek have provided a T-4 Sharpening System. Festool have provided a CTL 36 E CLEANTEC Dust Extractor.

The precision cut-away model showing exterior and interior details, will be built by students of South Devon Marine Academy, under the leadership and guidance of Captain Ian Kirkwood who has undertaken the project on behalf of the Dartmouth Museum.

With the backing of the UK government and US embassy in the UK, Mayflower 400 celebrations are expected to attract over a million visitors to Dartmouth, Plymouth and 10 other cities in the UK, Holland and the US, linked to the epic three-month voyage.

The Mayflower model will be a key attraction within the many special events planned from November 2019 to November 2020, and will become the centrepiece of a permanent display in the Dartmouth museum.

To mark the 400th anniversary of the Mayflower’s voyage to the New World in 1620, Axminster is helping to provide tools to help build a 3 metre replica of the icon ship.

Axminster’s manufacturing workshop has recently taken delivery of a new quarter of a million pound CNC machine from Star Micronics.

Japanese company Star Micronics is one of the world’s most respected manufacturers of Swiss-type turning machines. These machines produce small, complex and precise metal components. Star delivered the basic machine from Japan to their UK subsidiary – Star Micronics GB – based in Derby. There the factory built up the machine according to the customer’s needs. Then the company sourced parts from all over Europe and electronics from Taiwan. The complex hydraulic pump and swarf removal system were produced in the UK; the fume extraction system came from Sweden. As a result, this type of machine is unique to its manufacturer and has a relatively small market. This may explain why the bigger companies do not produce it.

The new lathe is the second Star machine Axminster has purchased to enhance its innovation and manufacturing capability. This lathe is much bigger, turning up to 38mm in diameter; the original model can only turn up to 32mm. Going forward, both machines will operate at the same time.

What are the benefits?

There are many advantages to the new machine and here are just some of them. Specialising in high precision small round components, the Star lathe works at a very high speed, producing hundreds of items each day that require no further finishing. Also, high speed production reduces the cost. What's more, Axminster engineers can programme the machine to select the correct cutter depending on what it is making, and it can cut a superior type of stainless steel. All of these factors have a knock-on benefit to the customer and end user in terms of quality and cost.

We make Parf Super dogs, parts for woodturning centres, spacers, pins and guides for the Parf guide system and pen turning mandrels. In the past we made these on a Mazak lathe, but it took a long time. With the Star machine the process is much, much quicker.

Keith Thompson (Innovation & Product Manager)

Skillful and precise installation

Installation of the new Star machine into Axminster’s production facility was a precise yet fairly straightforward operation. Star Micronics’ delivery and commissioning team craned the lathe off the vehicle onto low profile trolleys and wheeled it into the workshop. The only hitch occurred when the team found it was too long for the designated space, so some adjustments to the space had to be made. Once in place, the lathe was bolted to the floor. Being thicker, stable and unaffected by changes in the weather or temperature, this special floor guarantees the accuracy of the machine. Then the team built and commissioned the machine.

This is a quarter of a million pound machine we are adding to the machine shop, expanding our manufacturing capacity as we believe in manufacturing in Britain. Being a world-class manufacturer in today’s competitive world really does require huge investment, this being the second Star machine we have purchased in 18 months.

Ian Styles (Production Development Director)

-

UJK Super DogFrom £29.98 £24.98

-

Axminster Woodturning Pro DrivesFrom £49.98 £41.65

-

Axminster Woodturning Compression Pen MandrelFrom £59.98 £49.98

Axminster’s manufacturing workshop has recently taken delivery of a new quarter of a million pound CNC machine from Star Micronics. Japanese company Star Micronics is one of the world’s most respected manufacturers of Swiss-type turning machines. These machines produce small, complex and precise metal components. Star delivered the basic machine from Japan to their UK subsidiary – Star Micronics GB…

Last week we announced that the Axminster North Shields store would be moving sites. This week we report on how the move is going and what has been happening over the past few days.

Team effort

The North Shields team began de-merchandising and packing up the old store just over a week ago, and made good progress. Welcome assistance arrived from other parts of the company. This included Phil Lewis store manager from Warrington, Rob from Head Office and Amber, Rebecca and Mark from the warehouse in Axminster.

In addition, Axminster HGV driver Graham drove north from Devon to transport all the stock from one store to the other. The target was to get everything packed and ready to move to the new store over Thursday 7th and Friday 8th. Once fully packed up, the final pallet count was around 130 plus some machines and benches.

Focus on merchandising

And so, for the past few days the team have focused on getting the new store merchandised and ready to welcome back customers. As a result, the store is on target to be up and running and open for business from Friday 15th June.

Senior store manager John Flavell commented: “Huge thanks to those staff members who have come up from Devon and across from Warrington to help with the move. And, of course, to the North Shields team for their flexibility and commitment towards moving. The whole process has been a fantastic team effort. We're not quite fully merchandised yet, but a lot further ahead at this stage than we anticipated. Initially we thought it would take much longer than it has. But due to the efforts of all those involved, we're on course to be open and operational from Friday 15th June.”

The new address

The full address of the new store is Unit J1a Hamar Close, Tyne Tunnel Trading Estate, North Shields NE29 7XB.

Last week we announced that the Axminster North Shields store would be moving sites. This week we report on how the move is going and what has been happening over the past few days. Team effort The North Shields team began de-merchandising and packing up the old store just over a week ago, and made good progress. Welcome assistance arrived…