Grinding Wheels

Choosing a Grinding Wheel

When choosing a grinding wheel, there are a lot of things that you need to consider before you make your purchase, due to many different factors.

Here we take a look at the main factors behind your choice of a grinding wheel and the health and safety issues that need to be considered. Having read this buyer’s guide, you should not only have the right wheel for the job but also have taken the necessary precautions so that your use of the grinder is as safe as possible.

Health and Safety: A grinder can be one of the most dangerous machines in the workshop, which is mainly due to the wheels that are fitted to it. To ensure that you and your workplace are safe, we would recommend following certain guidelines.

Speed Rating: Before purchasing your wheel, check the running speed of your grinder as this should never be more than the wheel’s maximum speed. Running the wheel above its maximum rpm can be very dangerous and lead to it breaking or exploding.

Note: Some wheels are rated in metres per minute, whereas others are in revs per minute, so make sure calculations are done before fitting a new wheel.

Abrasive Wheels Course: In the work environment it is mandatory to have been on an abrasive wheels training course before working on this type of machine.

Wheel Integrity: All wheels should be examined after unpacking for any signs of damage that may have occurred during transit. If damage is seen or heard (using ‘ring’ test), the wheel must not be used and it should be returned back to the supplier.

Storage: Wheels should be stored in an area where they will not be susceptible to rough treatment or rooms where there are severe temperature fluctuations as this can damage the bond in the wheels.

Machine Set Up: Ensuring the machine is setup correctly at all times is paramount, making sure the guards are in place and tool rests adjusted to the correct clearance.

Personal Protective Equipment (PPE): Goggles should always be worn when grinding; when dressing, a suitable dust mask is also a must if dust extraction isn’t available. Other PPE such as overcoats are not essential but preferable.

Extraction / Ventilation: When dressing the wheel, suitable extraction should be used to remove the grinding debris.

Buying a Grinding Wheel

Main Considerations

Physical Size: The first thing to consider is to buy the appropriate wheel for the size of the grinder. A smaller diameter wheel will work on a larger grinder but this will affect the peripheral speed so it’s not recommended, as it will run more slowly.

Material to be Ground: The material will be ground or sharpened directly influences the kind of abrasive required in the wheel. i.e. tungsten carbide tools will need a ‘green’ silicon carbide wheel.

The Abrasive: There are a variety of different abrasives on offer, all of which have unique properties such as hardness and strength of bond making them suitable for different materials.

The Grit Size: This is defined by the task that you are completing. If a high removal rate of material is required then you will want a coarse grit i.e. 24g. Fine finishing needs a finer grit, such as 100g.

Glue / Bond: The bond is what holds the abrasive together in wheel and will once again be determined by the task undertaken. There are three main types of bonds:

- Vitrified bonds - Made primarily of clay, vitrified bonds are strong and very rigid. This is the best type of bond when a high stock removal is required.

- Organic bonds - Designed to operate at higher speeds, these bonds will soften under the heat of grinding. These are also good for high stock removal and jobs which require a better finish.

- Rubber bonds - Offering a smooth grinding action, these wheels are specifically used when a very high quality finish is required.

Speed Rating

The wheel must be used on a grinder that does not work above it’s safe operating speed as this may lead to breakage.

The Abrasive Materials

Aluminium Oxide

White Grinding Wheels: White grinding wheels are very friable as they’re made from pure Aluminium Oxide. The crystals break down very quickly, as those with dull cutting edges are replaced with fresh crystals with sharp cutting edges. Due to their friable nature these wheels will lose their shape very quickly and a dressing stick will have to be used frequently to prevent this from happening.

Suitable Materials: Steel

Uses: 60 and 80g suitable for roughing out tools; 100g for finishing

Benefits: Economically priced, cool cutting

Pink Grinding Wheels: Also made from Aluminium Oxide, these pink wheels have added Chromium Oxide, which explains the colour. This makes the grains of the wheel tougher and therefore the wheel keeps it’s shape for longer. Pink wheels are considered semi-friable.

Suitable Materials: Steel and some high speed steel

Uses: Grinding the fine edge on hand tools.

Benefits: Economically priced, resistance to grooving

Grey Grinding Wheels: Also made from Aluminium Oxide, these are ‘stock’ grinding wheels, very commonly supplied with the grinder. They are very tough and not ‘friable’.

Suitable Materials: Carbon steel

Uses: General workshop, production and rough grinding

Benefits: Very economically priced

Silicone Carbide

Green Grinding Wheels: ‘Green’ wheels have an extremely sharp grit, are very rigid and contain vitrified bonds, giving effective stock removal.

Suitable Materials: Tungsten carbide, titanium and the hardest steels

Uses: Precision grinding and surface finishing

Benefits: Economically priced and rigid; holds it’s shape very well

Cubic Boron Nitride

Cubic Boron Nitride Grinding Wheels (CBN): Sometimes considered a super abrasive, CBN is a similar product to synthetic diamonds. Unlike diamonds, CBN can withstand the heat of grinding and will not alter the temper in the steel, a common cause of bluntness.

Suitable Materials: High speed steels

Uses: Leaves a fine, even and sharp edge on any HSS tools

Benefits: No dressing or conditioning of the wheel is required and it will last for many years. In use, very few sparks are produced

Other Wheels Available

Microcrystalline

Made using new ceramic technology, these wheels run very cool and leave a sharper, longer lasting edge on tools when compared to Aluminium Oxide wheels.

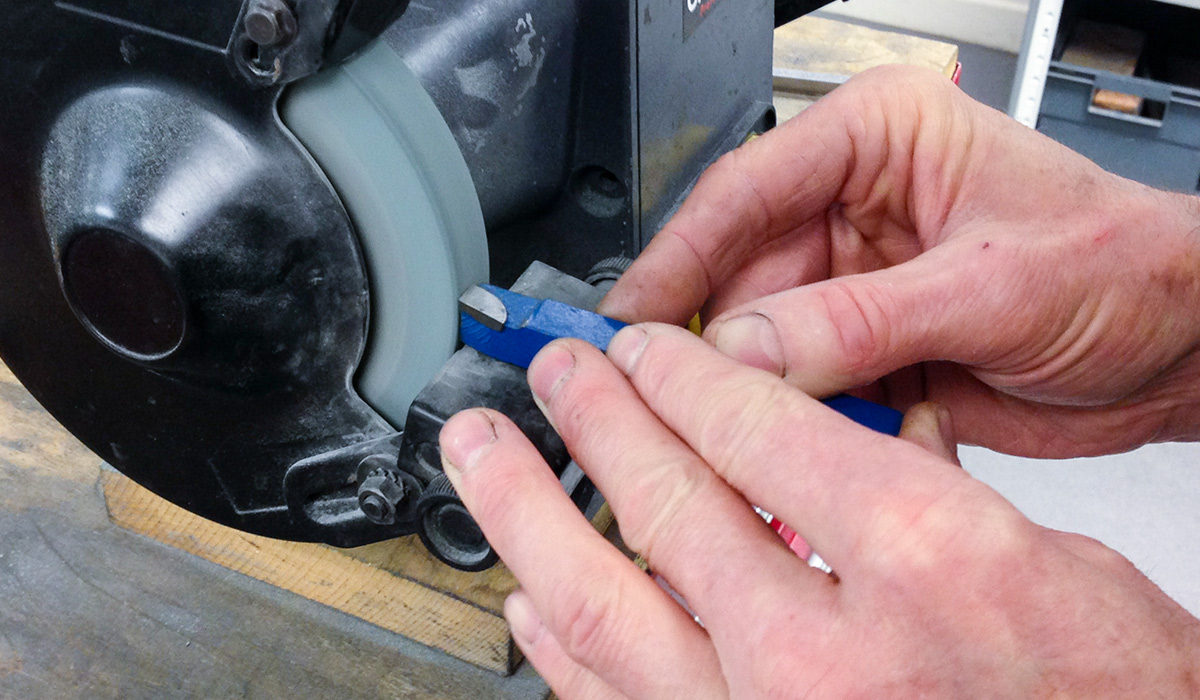

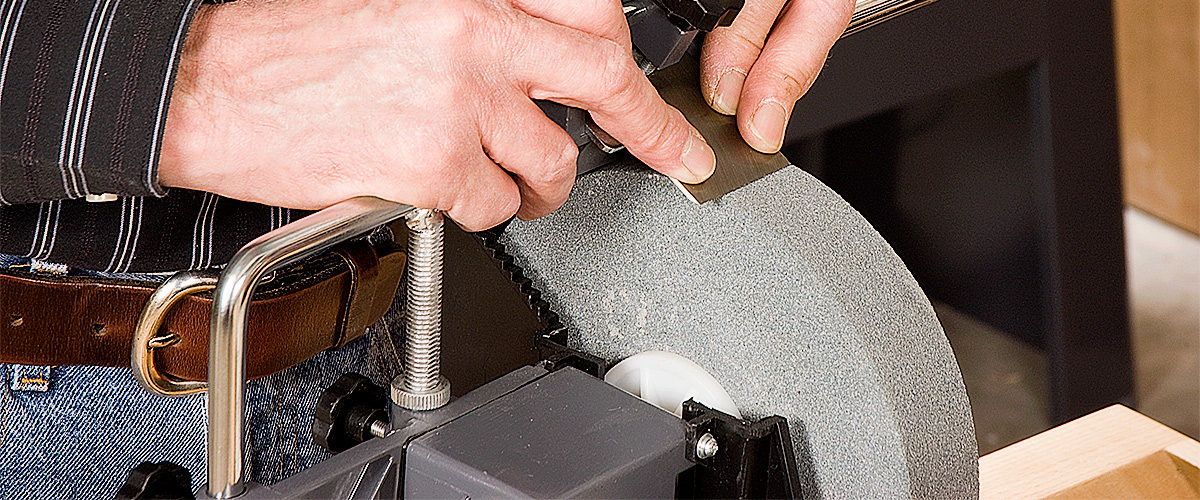

Wheel dressing

Wheel dressing is essential when grinding for a number of reasons.

- Cleans and removes metallic waste from the wheel

- Exposes fresh new abrasive edges, effectively providing fresh grit with sharp edges

- Trues the wheel, which minimises vibration and improves the finish

Good info. Thank you.