Great Accessories For Your Pillar Drill

Pillar drills play an important part in both the wood and metal working workshop. With accuracy being the main feature that sets them apart from their handheld cousins, people sometimes forget their versatility. Here we take a look at the accessories and consumables that will ensure your pillar drill is as precise and versatile as possible.

Drill bits; The types and applications

Drill bits; The types and applications

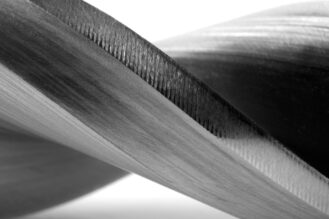

Getting the right drill bits for your pillar drill is very important. As was discussed in a recent article of ours, there are a plethora of drill bits out there. These vary in type and quality with both having an effect on the accuracy of your work. If you need a hand with the type of drill bit you need, then this guide would be a great help. For woodworking, two of the most popular types are forstner bits and brad point (lip and spur) drills. For the best quality bits out there, we recommend those from Austrian makers Fisch.

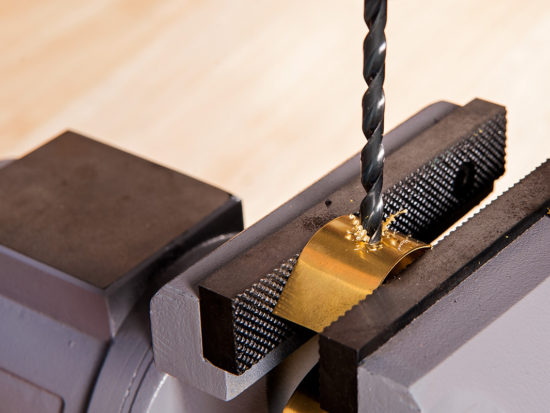

In metal working it's imperative to get drill bits made from a material that's hard and resistant to wear. The Swedish M2 grade steel in the Axminster M2 drill bit set is a better quality steel than standard HSS, making them extremely resistant. Adding a TiN (Titanium Nitride) coating also prolongs tool life, which is why this Ig2 set will perform in almost all metals. To prolong tool life further, it's important to use a lubricant. We recommend Ambersil and more specifically Tufcut metal cutting compound for your drilling tasks.

In metal working it's imperative to get drill bits made from a material that's hard and resistant to wear. The Swedish M2 grade steel in the Axminster M2 drill bit set is a better quality steel than standard HSS, making them extremely resistant. Adding a TiN (Titanium Nitride) coating also prolongs tool life, which is why this Ig2 set will perform in almost all metals. To prolong tool life further, it's important to use a lubricant. We recommend Ambersil and more specifically Tufcut metal cutting compound for your drilling tasks.

-

Axminster Professional 1.0-13 x 0.5mm TiN Coated HSS Drill Bit Set 25 PceFrom £95.98 £79.98

-

Ambersil Tufcut Metal Cutting CompoundFrom £21.28 £17.73 From £17.02

Workholding

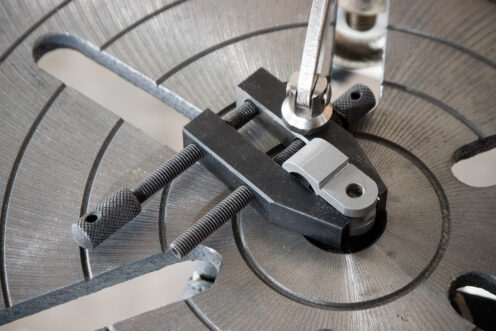

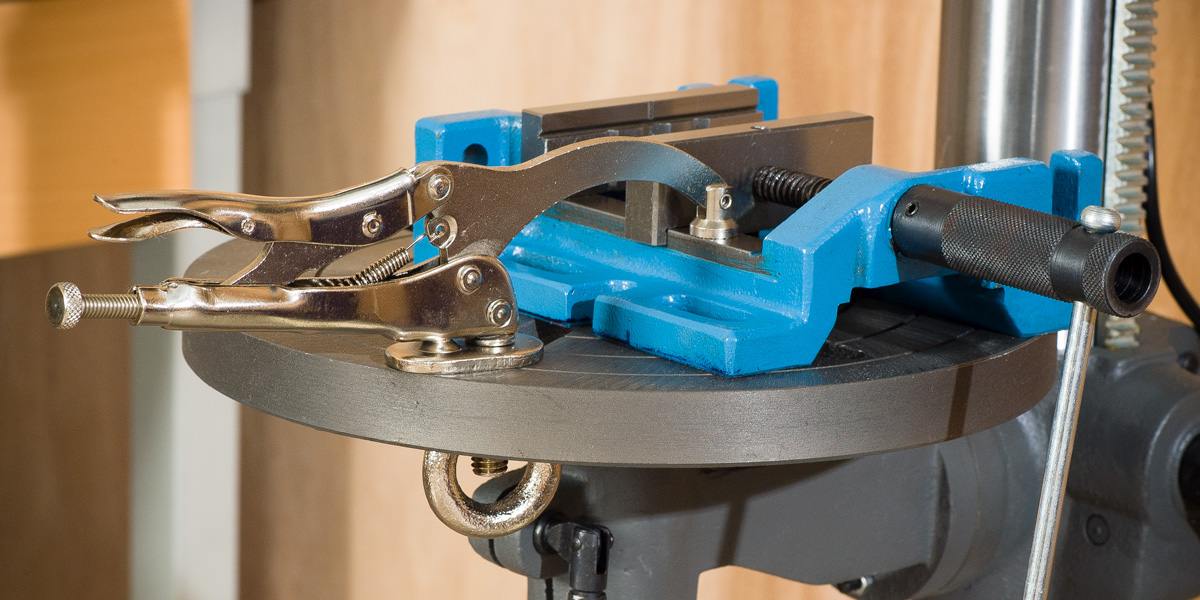

When drilling, a key safety recommendation is that you clamp your workpiece securely to the table. It will also aid the accuracy of the job being done. There are many different clamps and vices out there that can do this. In woodworking a simple G clamp or toggle clamp may suffice if the job is light. For heavier duty work it's better to use a drill vice, clamped securely to the table with a specially made drill clamp.

-

Axminster Professional Drill VicesFrom £35.98 £29.98

In metalworking you'll generally need a stronger, better made vice for stability and accuracy. The Axminster 3-way unigrip vice is fantastic for both wood and metal working. It is substantially constructed and can be used both vertically and horizontally. For the most precise tasks, the Axminster super precision vice is a must. For use on both pillar drills and mills, it is made from close grained, high tensile cast iron with the jaws parallel to within 30 microns! Working in the crafts? The Axminster toolmakers clamps are great for smaller jobs.

-

Axminster Engineer Series 3-Way Unigrip Vertical/Horizontal Drill ViceFrom £51.98 £43.32

-

Axminster Engineer Series Super Precision Machine Vice - 50mmFrom £113.98 £94.98

-

Axminster Engineer Series Tool Maker's ClampsFrom £6.98 £5.82

A versatile pillar drill?

That's right, pillar drills aren't just for drilling. They are actually an extremely versatile machine. Buy a large drum sander and turn your drill into an excellent bobbin sander. If you need to cut some mortices, this morticing attachment will convert your pillar drill into a lightweight morticing machine. It's best to check whether or not this is suitable for your drill first though. When doing both of these tasks, you will probably need more support than the standard table provides. TheAxminster pillar drill table will give you a 610mm x 305mm work area to support any larger projects, while also providing a base for customer made jigs.

-

Axminster Workshop Morticing AttachmentFrom £42.98 £35.82

Safety

Safety

With the workpiece being firmly held down by a clamp and/or vice, there are only a couple of safety considerations. Firstly, due to the waste being thrown by the cutting of the drill, it's very important to wear eye protection. Secondly, it could be very easy for clothing or even hair to be caught on the rotating spindles, so take precaution by tying hair back and be careful not to wear loose clothing.

Conclusion

A pillar drill is a great bit of equipment to have in the workshop, one that can be made even better by getting the right accessories. We hope that this has gone some way to helping you think about the items you need to improve yours.

If you are in the market for buying a pillar drill, we can certainly help you with that. This buying guide will give you an insight into the key features and how they will work for you...