Plunge Saws

All Things Plunge Saws

A hand held circular saw is a fairly basic and almost essential part of any workshop. Simplistically, a motor, saw-blade together with it's spring loaded retractable guard are pivoted above a base plate. Undoing the locking mechanism allows the blade to drop beneath the base plate. This sets the desired depth of cut. With the saw blade locked at the correct depth for the material, the guard retracts behind the blade as the cut proceeds, springing back to completely cover the blade once finished.

Common features of all plunge saws

A relatively recent innovation has been the development of the 'track saw' which differs from a conventional circular saw in a number of important ways. The motor and blade assembly (the top half of which is completely covered) is still mounted above the base plate, but now the whole assembly is sprung loaded and there's no retractable blade guard to obscure the saw cut. As a result, the blade can be plunged vertically past the side of the base directly into the work. This means that the cut could begin in the middle of a large board, whereas with a conventional circular saw, it's customary to start at one edge.

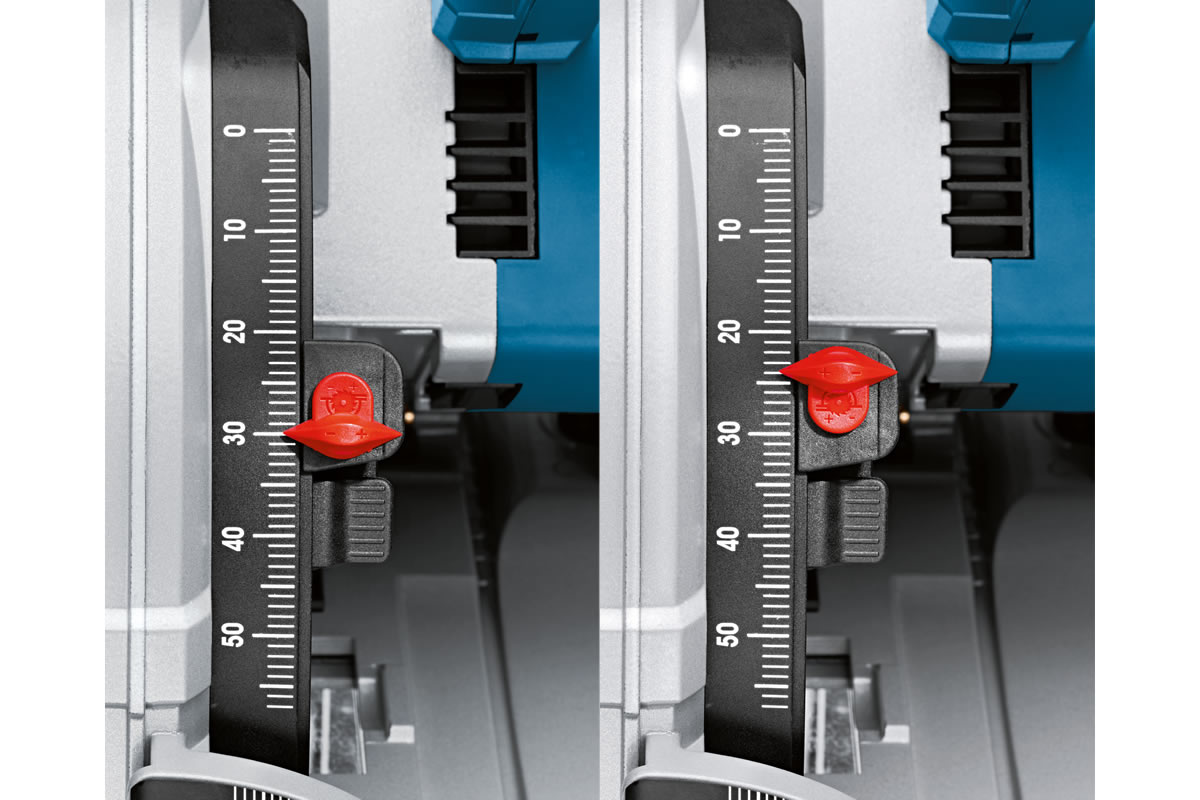

Depth of Cut

The depth of cut can be accurately pre-set and the riving knife is spring supported so that it retracts automatically into the housing when the saw is plunged. As the saw is pushed forward, the riving knife drops down behind the cutter so the blade doesn't bind, ensuring a safe cut. The plunge saw comes into its own when complex apertures and cut-outs need to be produced as it allows total control of the machine at the beginning and completion of a cut. The flush housing also enables these saws to plunge and cut very close to the edge of a wall, which is a useful feature when cutting flooring to size.

Track & Splinter Guard

These types of saws are usually used with a extruded aluminium track which produces a dead straight and very accurate cut. All makes incorporate a 'splinter guard' which minimises splintering on the top surface of the board. The strip is affixed to the edge of the track and is cut by the saw blade the first time it's used. Thereafter, it supports the upper face of the material whilst it's being cut. Provided that the splinter guard is correctly lined up with the 'start' and 'finish' marks on the board, a track saw will cut with remarkable accuracy.

Tracks can be joined seamlessly together to form an extended guide enabling a long cut down the length (or even longer if required) on a full sheet of mdf or plywood and are securely fixed to the board with a pair of special ratchet lever clamps. As well as plunging vertically through the material, the motor housing and blade can also be beveled and locked from 0-47° for mitred or coopered work.

Dust Extraction

In common with many power tools, these plunge saws can be connected to a vacuum extractor to remove the sawdust. The dangers of wood waste can't be overstated and if MDF is being sawn, the extractor should be to class 'M' specification.

Voltage

An important aspect of all plunge saws is that they are offered either as 230V or 110V, which make them suitable for site work.

Need help?

If you still can’t decide on which sander to choose, why not get in touch with one of our Axminster Experts? Either pop into your local Axminster store and chat with our experienced sales advisors, call our dedicated Customer Services team for advice or talk to us through our Online Chat function on our website. As always, you can get in touch and ask questions via any of our social media platforms. We are here to help you!

Discover more...

If you’ve enjoyed reading this Buying Guide, why not take a look at our other Power Tools Buying Guides? From How to Choose Your Next Power Tool Dust Extractor to overviews on Drill Types, Multitools, Routers and Sanders, we’ve got something for everyone.

Hello Dears

I am a fan of your excellent products and I already have some of your products like jigsaw, router, . . .

I am a sign maker and I need one of your circular saws to cut composite aluminium sheets, Acrylic sheets, PVC foam sheet, plastic sheets, ...

I'm really confused which one of your saw is suitable for the type of job I need and most importantly what kind of blades.

I would be so thankful if you could please help and advise me to choose the best